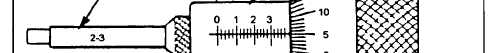

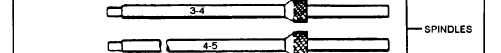

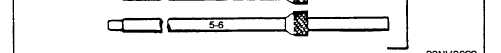

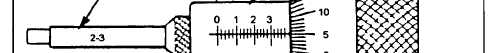

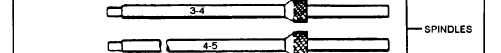

Figure 2-28.—Inside micrometer set.

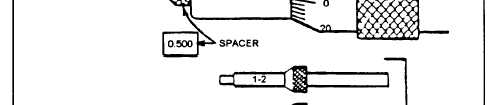

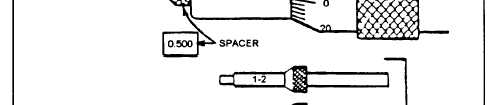

The 0.500 spacing piece is used between the spindle

and the micrometer head so the range of the micrometer

can be extended. A knurled extension handle is usually

furnished for obtaining measurements in hard-to-reach

locations.

Reading the inside micrometer. To read the inside

micrometer, read the micrometer head exactly as you

would an outside micrometer, then add the micrometer

reading to the rod length (including spacing collar,

when installed) to obtain the total measurement.

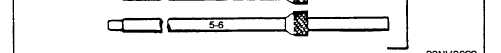

Depth Micrometer

The depth micrometer is used to measure the

precise depths of holes, grooves, and recesses by using

interchangeable rods to accommodate different depth

measurements (fig. 2-21). When using a depth

micrometer, you must make sure the base of the

micrometer has a flat, smooth surface to rest on and

that it is held firmly in place to ensure an accurate

measurement (fig. 2-29).

Reading a depth micrometer. When reading a

depth micrometer, you will notice that the graduations

on the sleeve are numbered in the opposite direction of

those on an outside or inside micrometer. When you are

reading a depth micrometer, the distance to be measured

is the value that is covered by the thimble. See figure

2-30; consider the reading shown. The thimble edge is

between the numbers 4 and 5. This shows a value of at

least 0.400 inch on the sleeve’s major divisions. The

thimble also covers the first minor division on the

sleeve; this has a value of 0.025 inch. The value shown

on the thimble circumference scale is 0.010 inch.

Adding these three values together results in a total of

0.435 inch, or the total distance that the end of the

extension rod has traveled from the base. This

measurement added to the length of the extension rod

Figure 2-29.—Using a depth micrometer.

2-11