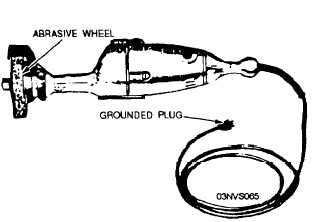

Figure 1-64.-Portable electric sander.

preparation for painting. This machine, however,

must not be used where a mirror-smooth finish is

required.

The disk should be moved smoothly and lightly

over the surface. Never allow the disk to stay in one

place too long, because it will cut into the metal and

leave a large depression.

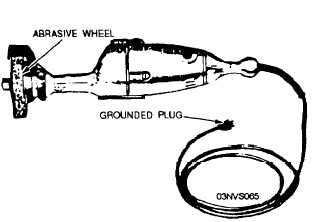

PORTABLE GRINDERS

Portable grinders are power tools that are used for

rough grinding and finishing of metallic surfaces.

They are made in several sizes; however, the one used

most in the Navy uses a grinding wheel with a

maximum diameter of 6 inches. See figure 1-65.

The abrasive wheels are easily replaceable so that

different grain size and grades of abrasives can be

used for the various types of surfaces to be ground

and the different degrees of finish desired.

A flexible shaft attachment is available for most

portable grinders. This shaft is attached by removing

the grinding wheel, then attaching the shaft to the

grinding wheel drive spindle. The grinding wheel can

then be attached to the end of the flexible shaft. This

attachment is invaluable for grinding surfaces in

hard-to-reach places.

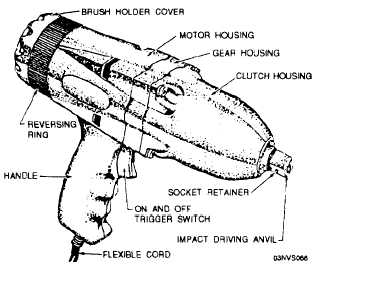

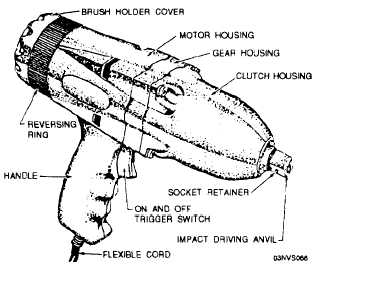

ELECTRIC IMPACT WRENCH

The electric impact wrench (fig. 1-66) is a

portable, hand-type reversible wrench. The one

shown has a 1/2-inch-square impact driving anvil,

over which 1/2-inch-square drive sockets can be fitted.

Wrenches also can be obtained that have impact

driving anvils ranging from 3/8 inch to 1 inch. The

driving anvils are not interchangeable, however, from

one wrench to another.

The electric wrench with its accompanying

equipment is primarily intended for applying and

removing nuts, bolts, and screws. It may also be used

to drill and tap metal, wood, plastics, and so on, and

to drive and remove socket-head, Phillips-head, or

slotted-head wood, machine, or self-tapping screws.

Before you use an electric impact wrench, depress

the on-and-off trigger switch and allow the electric

wrench to operate a few seconds, noting carefully the

direction of rotation. Release the trigger switch to

stop the wrench. Turn the reversing ring, located at

the rear of the tool; it should move easily in one

direction (which is determined by the current direction

of rotation). Depress the on-and-off trigger again to

start the electric wrench. The direction of rotation

should now be reversed. Continue to operate for a

Figure 1-65.-Portable grinder.

Figure 1-66.-Reversible electric impact wrench.

1-38