work. If the blades are not at right angles to the surface

of the work, the edges of the cut will be slightly bent

and burred. The bench edge will also act as a guide

when you are cutting with the snips. The snips will

force the scrap metal down so that it does not interfere

with cutting. Any of the hand snips may be used for

straight cuts. When notches are too narrow to be cut

out with a pair of snips, make the side cuts with the

snips and cut the base of the notch with a cold chisel.

Safety and Care

Learn to use snips properly. They should always

be oiled and adjusted to permit ease of cutting and to

produce a surface that is free from burrs. If the

blades bind or if they are too far spat, the snips

should be adjusted. Remember the following safety

tips:

Never use snips as screwdrivers, hammers, or

pry bars. They break easily.

Do not attempt to cut heavier materials than

the snips are designed for. Never use tin snips to cut

hardened steel wire or other similar objects. Such use

will dent or nick the cutting edges of the blades.

Never toss snips in a toolbox where the

cutting edges can come into contact with other tools.

This dulls the cutting edges and may even break the

blades.

When snips are not in use, hang them on

hooks or lay them on an uncrowded shelf or bench.

HACKSAWS

Hacksaws are used to cut metal that is too heavy

for snips or boltcutters. Thus metal bar stock can be

cut readily with hacksaws.

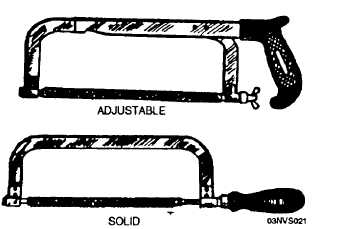

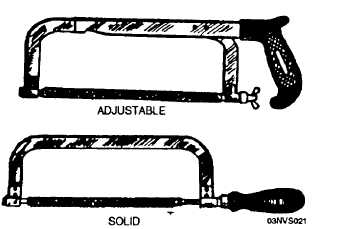

There are two parts to a hacksaw: the frame and

the blade.

Common hacksaws have either an

adjustable or a solid frame (fig. 1-21).

Most

hacksaws found in the Navy are of the

adjustable-frame type. Adjustable frames can be made

to hold blades from 8 to 16 inches long, while those

with solid frames take only the length blade for which

they are made. This length is the distance between

the two pins that hold the blade in place.

Figure 1-21.-Hacksaws.

Hacksaw blades are made of high-grade tool steel,

hardened and tempered. There are two types, the

all-hard and the flexible. All-hard blades are hardened

throughout, whereas only the teeth of the flexible

blades are hardened. Hacksaw blades are about

1/2-inch wide, have from 14 to 32 teeth per inch, and

are from 8 to 16 inches long. The blades have a hole

at each end, which hooks to a pin in the frame. All

hacksaw frames, which hold the blades either parallel

or at right angles to the frame, are provided with a

wingnut or screw to permit tightening or removing the

blade.

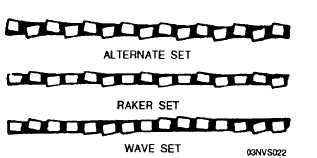

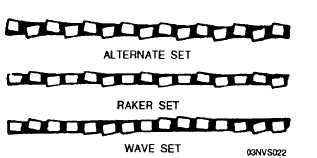

The SET in a saw refers to how much the teeth

are pushed out in opposite directions from the sides of

the blade. The four different kinds of set are the

ALTERNATE set, DOUBLE ALTERNATE set,

RAKER set, and WAVE set. Three of these are

shown in figure 1-22.

The teeth in the alternate set are staggered, one to

the left and one to the right throughout the length of

the blade. On the double alternate set blade, two

ajoining teeth are staggered to the right, two to the

Figure 1-22.-“Set” of hacksaw-blade teeth.

1-14