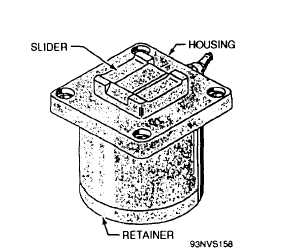

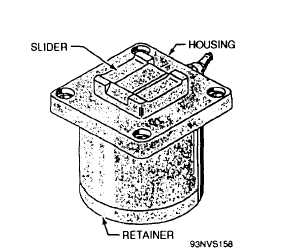

Figure 5-12.—Nose-gear-launch actuator reset assembly.

the slider provide for the flow of lubricant between

the slider and the inner walls of the housing. The

slider actuating spring is housed in a hole in the

bottom of the slider. The slider and spring are

secured in the housing by means of the retainer.

During operation when the slide assembly is

forward, the reset-assembly slider is not restrained

by the actuator assembly but is held above the

surface of the housing by the slider actuating spring.

After launch, as the slide assembly retracts, the

actuator-assembly

reset

tooth contacts

the

reset-assembly-slider pad surface, causing the

actuator assembly to rotate downward. This action

permits the buffer hook to drop below the deck

through the track opening into the deck housing

cavity (see diagram B, fig. 5-11). When the buffer

hook is below deck, the reset-assembly slider is held

down in the housing by the actuator assembly.

NOSE-GEAR-LAUNCH BUFFER CYLINDER

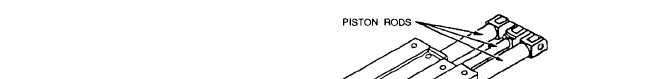

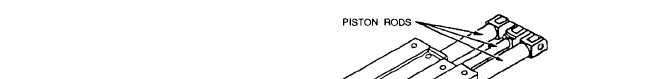

The NGL buffer cylinder (see fig. 5-13) is in the

deck housing between the NGL approach track and

the aft slide-access track. The buffer-cylinder body

has integral guide tracks on its top surface and

contains three hydraulic cylinders. The two outer

cylinders contain hollow piston rods; the center

cylinder piston rod is solid. The forward end of

each piston rod is attached to the NGL slide.

Within each outer rod is an orifice tube, which

meters fluid flow through the outer cylinders to

absorb the forward energy of the aircraft hookup;

the three piston rods are fully retracted into the

cylinders, and hydraulic fluid is constantly circulated

between the hydraulic system and the buffer

cylinder, bypassing the cylinders through two

metering orifice screws. This metered flow, which

is nonadjustable, prevents overheating of the

hydraulic fluid.

When the aircraft holdback bar engages the

buffer hook, the slide assembly moves forward,

pulling the three piston rods from the cylinders. As

the rods move forward, fluid in front of each

outer-cylinder piston is forced through the holes

around the periphery of each outer-cylinder piston

and through the metering holes in the two orifice

tubes. As the pistons continue forward, the number

Figure 5-13.—Nose-gear-launch buffer cylinder.

5-14