WARNING

Do NOT flux wire rope terminals.

CAUTION

Immerse wires carefully so the flux

solution does not enter the core of

hemp-center-type wire rope.

Immerse the grit-blasted wires in the

solution to within 1 inch of the top of the

seizing for 5 minutes.

5. Remove the wire rope from the solution,

shake, and turn the broomed end upright at once.

Then allow it to dry for 5 minutes. Any evidence of

rust on the wires after the flux-dry period will

necessitate refluxing.

Preparing the Terminals

Using a degreased length of seizing wire,

suspend the terminal from the top of the ultrasonic

degreaser so it is submerged in the solution. Allow

10 minutes for the decreasing operation. Inspect

the terminal and repeat the procedure if necessary.

Rinse the terminal in a bucket of clean GRISOLVE

MT-N for 30 seconds, then let air-dry for 5 minutes.

NOTE

Replace the solution in the ultrasonic

degreaser after 10 terminals have been

cleaned/degreased.

Replace the rinsing

solution after 10 terminals have been rinsed

or as soon as the solution becomes cloudy.

Lay the terminal in the grit blast cabinet. Plug

the cable entry hole with the rubber plug hanging

from the cabinet. Secure the doors on the side.

Grit blast the internal surfaces of the terminal from

both ends. Rotate the terminal so that the entire

internal surface is blasted.

Remove the terminal, invert it, and shake it

thoroughly to remove residual grit.

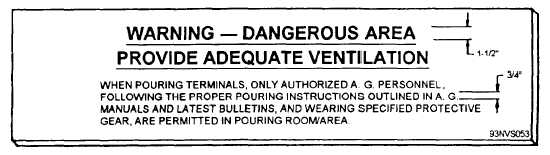

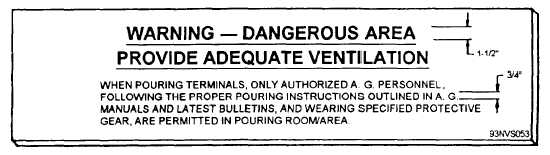

WARNING

To keep arresting gear crews constantly

aware of the health hazards associated with

the present terminal pouring procedures,

safety warning placards, fabricated by ship’s

forces, will be posted in clearly visible

locations in the arresting gear terminal

pouring rooms/area. (See fig. 3-53.)

Preparing and Pouring Zinc

NOTE

Use only special high-grade zinc NAEC

PN323822-2. No other is acceptable.

WARNING

Personnel engaged in preparing and/or

pouring molten zinc must wear protective

clothing, such as goggles and gloves. A

protective screen must be provided around

the pouring station.

A melting pot and furnace are used to melt the

zinc. Use a ladle that is thoroughly dry and free

from rust, scale, slag, or any other foreign matter.

The quantity of zinc prepared should be sufficient

for pouring several terminals and should be ready

prior to placing the terminals on the wire rope.

Figure 3-53.—Safety placard for terminal-pouring rooms

3-56