—If this appears to be the trouble, remove the

adjusting screw housing, loosen the jam nut, and

turn the adjusting screw clockwise until it bottoms.

This should close the pressure-relief control valve. If

this was the trouble, the pressure settings should be

re-adjusted as outlined in the operating instructions.

The fueling valve diaphragm may be ruptured.

This occurrence is very unlikely. However, if all other

steps have been followed and indications are that the

main valve is faulty, follow these steps:

1. Remove all fittings from the cover of the

fueling valve.

2. Remove the nuts holding the cover in place

and lift off the cover.

3. Lift the diaphragm assembly out of the valve

and examine the diaphragm for any holes.

4. Replace the diaphragm with a new one if

necessary.

5. While the diaphragm assembly is out of the

valve, the disk should be checked to see that it is in

good condition. Replace if necessary.

6. When reassembling the valve, make sure the

internal spring fits into its recess in the cover.

7. When the valve is returned to service, follow

the procedure outlined in the operating instructions.

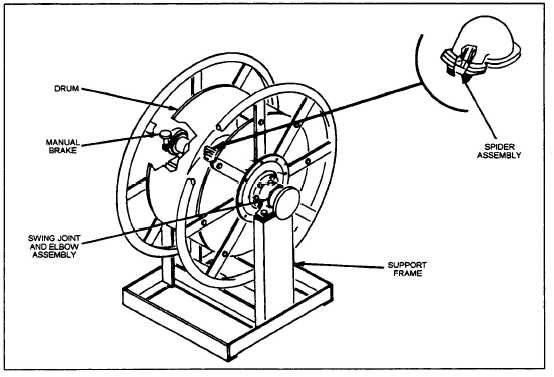

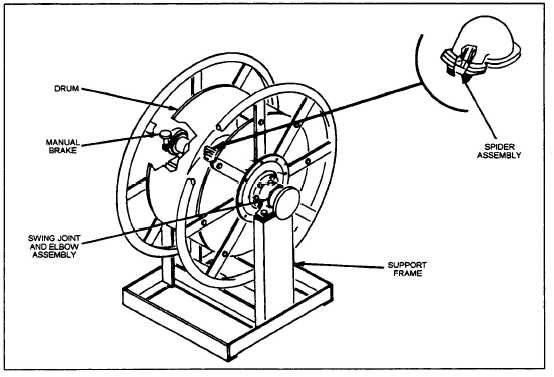

HOSE REELS

Each hose reel assembly (fig. 5-11) stores 150

feet of 2 1/2-inch collapsible hose or 1 1/2-inch non-

collapsible hose. Each hose reel assembly consists of a

drum, swing joint and elbow assembly, a support

frame, and a manual brake. The drum holds, reels,

and unreels the hose. The swing joint and elbow

assembly permits rotation around the central axis of

the drum, and also houses a spider assembly for the

continuity circuit. The support frame provides

permanent mounting for each drum. The manual

brake prevents the drum from rotating when not in

use.

The swing joint (fig. 5-12) is made of brass, to

resist corrosion. The continuity wire enters the top of

the flange on the fuel inlet side of the swing joint. It

is connected to an amphonel stud that is insulated

from the brass to prevent grounding out. Both ends of

the stud have very small O-rings that are held in

place by flat washers. The washers are, in turn, held

in place by nuts that are threaded on to the amphonel

stud.

Figure 5-11.—Hose reel assembly.

5-10