Sticking Valve Stems

There are several of conditions that may cause

valve stem troubles. If the packing is packed too

tightly, or if the gland nuts are tightened unevenly,

the valve stem is likely to stick or bind. Backing off

on the gland nuts relieves the packing pressure.

Paint or rust on the valve stem, which also causes

binding, can be removed by cleaning the stem.

The valve may become stuck if the valve stem

threads are burred from rough handling or upset

from pressure that has been applied to move sticking

and tight valves. Distorted or burred valve stem

threads are very serious valve troubles. If the valve

cannot be moved by any other method, the bonnet

must be re-moved, the stem cut out of the yoke or

bonnet, and a new stem made. If the bonnet or yoke

is damaged, it also must be repaired or replaced. If

burred or upset threads are detected before the stem

becomes stuck, they can be dressed smooth with a file

or machined in a lathe. If the sticking is due to a bent

valve stem. the stem must be straightened or

replaced.

MANIFOLDS

Manifolds are an integral part of the JP-5 below

decks systems. They consist of several valves

mounted in a compact unit, which provides a means

of controlling the flow of JP-5 to and from several

tanks at one central location.

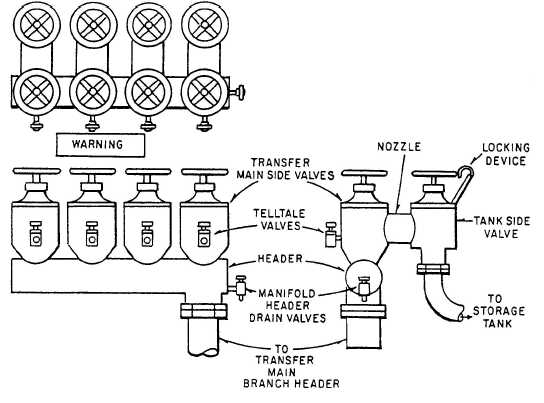

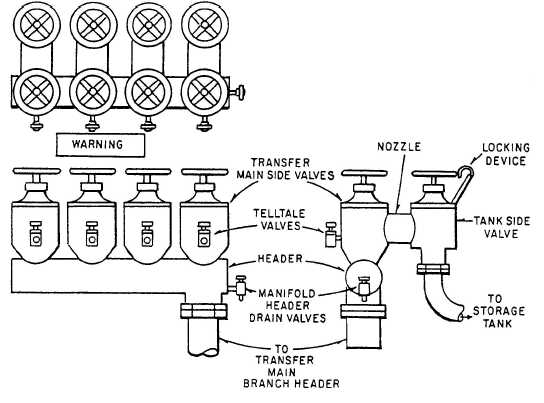

Double-Valved Manifolds

Double-valved manifolds (fig. 4-19) control the

flow of JP-5 to and from storage tanks that are

designated storage or ballast. They give double

protection against contaminating the transfer main

when the storage tanks are filled with seawater by

having two valves for one tanktop. These valves are

known as the transfer mainside valve and the

tankside valve.

The manifold HEADER is a section of pipe with

several equally spaced holes in the top to accommo-

date the transfer mainside valves. It is sealed on both

ends and has a pipe flange welded to the bottom. This

pipe flange is bolted to a section of pipe leading off

the transfer-main branch header.

Figure 4-19.—Double-valved manifold.

4-23