purpose and should be used only on the objects they

are designed for. When you use a hand tool for other

purposes, you usually damage both the tool and the

object it is used on. Use screwdrivers to drive and

remove screws. Do not use them to scrape paint, as a

pry bar or chisel, and certainly never use them to test

an electrical circuit.

STANDARD SCREW

DRIVER

Three main parts make up the construction of the

standard screwdriver (fig. 2-1, view A), the handle,

the shank, and the end. The end (called the blade) fits

into the screw slot. When using a screwdriver, select

the proper size blade for the job intended. A blade too

large or too small causes the screwdriver blade and

the screwhead to become damaged. At least 75 per-

cent of the screw slot should be filled by the blade for

proper fit.

PHILLIPS HEAD

SCREWDRIVER

A Phillips head screwdriver (fig. 2-1, view B)

differs in construction from a standard screwdriver

only in that the tip is shaped to fit the special cavity in

the Phillips screwhead. A standard screwdriver must

never be used in a Phillips screwhead as damage will

occur to it. The Phillips cavity should be filled com-

pletely by the selected driver for proper fit.

HAMMER

The hammer (fig. 2-1. view G) most used by the

ABF is the ball peen. The ball peen hammer is used

for working metals, such as chiseling rivets and shear-

ing metal.

COMBINATION PLIERS

Combination pliers (fig. 2-1, view C) are manu-

factured with straight serrated jaws for gripping ob-

jects. The pivots, with which the jaws are attached, are

adjustable to fit different size objects. Pliers should

not be used to grasp the shanks of screwdrivers to gain

greater twisting force.

DIAGONAL PLIERS

Diagonal pliers (fig. 2-1, view D) are used only

for cutting small material such as wire or cotter pins.

They are designed specifically for cutting. They

should NOT be used for grasping objects such as nuts

and bolts.

ADJUSTABLE WRENCHES

An adjustable wrench (fig. 2-1, view E) is not

intended to replace an open-end wrench, but it is

useful in working in restricted areas. In addition, it

can be adjusted to fit odd-sized nuts or bolts. This

wrench is often called a knuckle buster because me-

chanics frequently suffer the consequences of using it

improperly.

PIPE WRENCHES

A pipe wrench (fig. 2-1, view F) is primarily used

for rotating round stock and/or various pipes and pip-

ing. The most common pipe wrench is the Stillson. It

has two jaws that have serrated teeth to provide a

gripping ability. The larger jaw is a fixed jaw. The

smaller jaw is adjustable and the weaker of the two

jaws. Whenever a Stillson wrench is used, it should be

applied in such a manner that the fixed jaw provides

the twisting force. These wrenches also come in vary-

ing lengths, which makes the jaw sizes vary. A Still-

son wrench should never be used on machined

surfaces, as the teeth tend to mar or otherwise ruin the

metal.

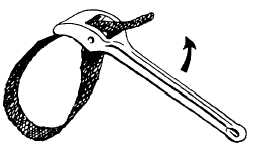

The strap wrench (fig. 2-2) should be used instead

of a Stillson to eliminate damage to soft metals. The

strap wrench employs a heavy nylon strap. One end is

attached to the wrench handle. while the other end is

free to pass around the object to be rotated, and then

back through the locking device provided on the

wrench handle.

SPANNER WRENCHES

Many special nuts are made with notches cut into

their outer edge. For these nuts a hook spanner

Figure 2-2.—Strap wrench.

2-2