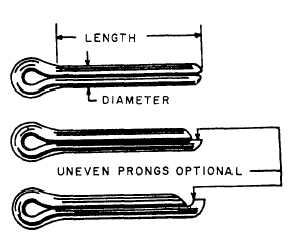

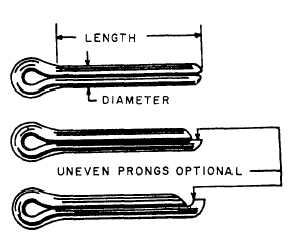

Figure 2-57.—Types of cotter pins.

AIRCRAFT SAFETYING METHODS

Learning Objective:

Identify the various

safety methods used on aircraft hardware.

You will come in contact with many different

types of safetying materials. These materials are used

to stop rotation and other movement of fasteners.

They are also used to secure other equipment that may

come loose due to vibration in the aircraft.

COTTER PINS

Cotter pins are used to secure bolts, screws, nuts,

and pins. Some cotter pins are made of low-carbon

steel, while others consist of stainless steel and are

more resistant to corrosion. Also, stainless steel

cotter pins may be used in locations where

nonmagnetic material is required. Regardless of

shape or material, all cotter pins are used for the same

general purpose—safetying. Figure 2-57 shows three

types of cotter pins and how their size is determined.

NOTE: Whenever uneven prong cotter pins

are used, the length measurement is to the end

of the shortest prong.

SAFETY WIRE

Safety wire comes in many types and sizes. You

must first select the correct type and size of wire for

the job. Annealed corrosion-resistant wire is used in

high-temperature, electrical equipment, and aircraft

instrument applications. All nuts except the

self-locking types must be safetied; the method used

depends upon the particular installation.

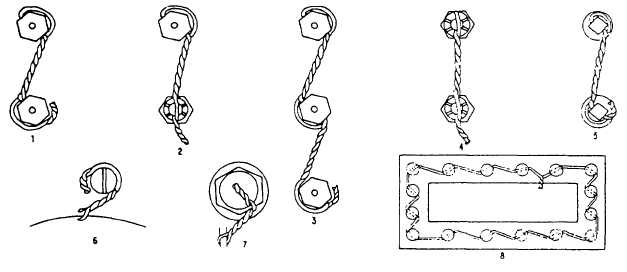

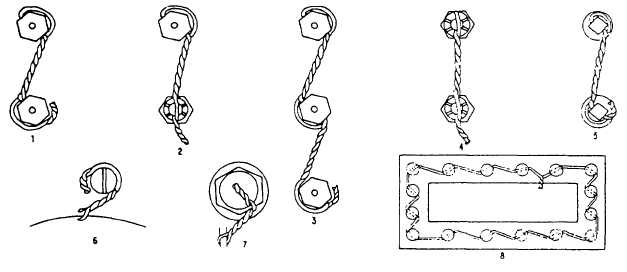

Figure 2-58 shows various methods commonly

used in safety wiring nuts, bolts, and screws.

Examples 1, 2, and 5 of figure 2-58 show the proper

method of safety wiring bolts, screws, square head

plugs, and similar parts when wired in pairs.

Examples 6 and 7 show a single-threaded component

wired to a housing or lug. Example 3 shows several

components wired in series. Example 4 shows the

proper method of wiring castellated nuts and studs.

Note that there is no loop around the nut. Example 8

shows several components in a closely spaced, closed

Figure 2-58.—Safety wiring methods.

2-45