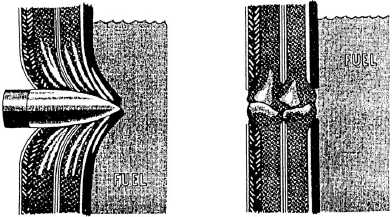

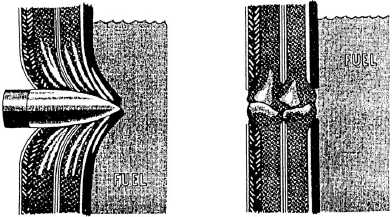

Figure 3-31.—Bullet sealing action.

by leaking fuel. It keeps the aircraft’s fuel intact so the

aircraft may continue operating and return to its base.

The most commonly used types of self-sealing fuel

cells are the standard construction type and the type

that uses a bladder along with the self-sealing cell. Of

the two, the standard construction cell is used the

most. It is a semiflexible cell, made up of numerous

plies of material.

The combination bladder and self-sealing cell is

made up of two parts. One part is a bladder-type cell,

and the other part is identical to the standard

construction cell. It is designed to self-seal holes or

damage in the bottom and the lower portions of the

side areas. The bladder part of the cell (nonself-sealing)

is usually restricted to the upper portion. This type of

cell is also semi flexible.

SELF-SEALING

CELL

(STANDARD

CONSTRUCTION).— There are four primary layers

of materials used in the construction of a self-sealing

cell. These layers are the inner liner, nylon fuel

barrier, sealant, and retainer. All self-sealing fuel cells

now in service contain these four primary layers of

materials. If additional plies are used in the

construction of the cell, they will be related to one of

the primary plies.

The inner liner material is the material used inside

the cell. It is constructed of Buna N synthetic rubber.

Its purpose is to contain the fuel and prevent it from

coming in contact with the sealant. This will prevent

premature swelling or deterioration of the sealant.

Buna rubber is an artificial substitute for crude or

natural rubber. It is produced from butadiene and

sodium, and is made in two types, Buna S and Buna N.

The Buna S is the most common type of synthetic

rubber. It is unsuitable for use as inner liner material

in fuel cells. It causes the petroleum fuels used in

aircraft to swell and eventually dissolve. The Buna N is

not affected by petroleum fuels, making it ideal for this

application. However, the Buna N is slightly porous,

making it necessary to use a nylon barrier to prevent

the fuel from contacting the sealant.

The nylon fuel barrier is an unbroken film of nylon.

The purpose of the nylon fuel barrier is to prevent the

fuel from diffusing farther into the cell. The nylon is

brushed, swabbed, or sprayed in three or four hot coats

to the outer surface of the inner liner during

construction.

The sealant material is the next material used in

fuel cell construction. It remains dormant in the fuel

cell until the cell is ruptured or penetrated by a

projectile. It is the function of the sealant to seal the

ruptured area. This will keep the fuel from flowing

through to the exterior of the fuel cell (fig. 3-31.)

The mechanical reaction results because rubber,

both natural and synthetic, will “give” under the shock

of impact. This will limit damage to a small hole in the

fuel cell. The fuel cell materials will allow the projectile

to enter or leave the cell, and then the materials will

return to their original position. This mechanical

reaction is almost instantaneous.

The chemical reaction takes place as soon as fuel

vapors penetrate through the inner liner material and

reach the sealant. The sealant, upon contact with fuel

vapors, will extend or swell to several times its normal

size. This effectively closes the rupture and prevents

the fuel from escaping. The sealant is made from

natural gum rubber.

3-45