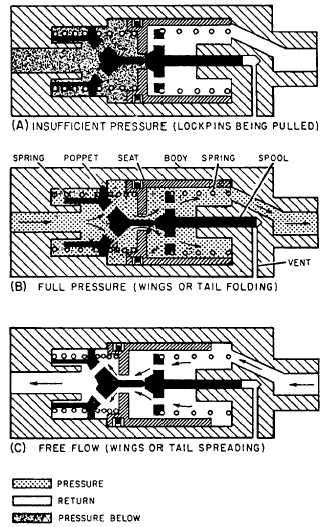

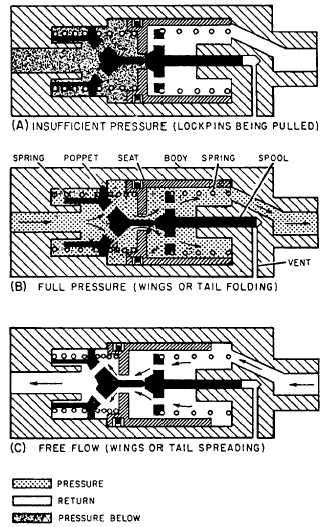

Pressure-Operated (Priority) Sequence Valve

The pressure-operated sequence valve, also called

a priority valve, looks like a check valve externally.

Like a check valve, the installation position is

indicated by an arrow. Figure 8-14 shows this valve

installed in a wing fold system.

During the wing folding cycle, pressure-operated

(priority) valves sequence the movement of the

lockpins and fold actuators. These valves ensure

lockpin actuation before fold actuator operation. This

completely automatic valve consists of a body

containing a spool, seat, poppet, related springs, seals,

and an end cap.

When the wing fold selector valve is in the fold

position, it directs fluid both to the wing lockpin and

to the pressure-operated sequence (priority) valve.

System pressure drops in the wing fold system

because of the amount of pressurized fluid needed to

actuate the lockpins. This lowers pressure below that

needed to open the pressure-operated (priority) valve.

View A of figure 8-14 shows insufficient pressure

to unseat the spool. When lockpins have completed

their travel, system pressure builds until it overcomes

spring tension and causes the poppet to unseat the

spool (view B of fig. 8-14). Fluid then flows freely

through the valve to the wing fold actuators.

View C of figure 8-14 shows the free-flow

position of the valve.

When spreading the wings,

return fluid moves the seat from the spool

compressing the poppet spring, which causes the

poppet to bottom and allows free flow of fluid

through the valve.

SHUTTLE VALVES

All aircraft incorporate emergency systems that

provide alternate methods of operating essential

systems required to land the aircraft safely. These

emergency systems usually provide pneumatic or

hydraulic operation of the essential systems; however,

in some cases due to the design, they maybe operated

satisfactorily through mechanical linkage. When

using the pneumatic or hydraulic emergency system,

that pressure must be directed to the unit concerned;

emergency pressure must not enter the normal

system, especially if the pneumatic type system is

used. To allow operating pressure to reach the

actuating unit and still not enter the other system, a

shuttle valve is installed in the working line to the

actuating unit. The main purpose of the shuttle valve

Figure 8-14.—View of priority valve.

is to isolate the normal system from the emergency

system.

Shuttle valves are located close to the actuating

unit concerned. This location reduces to a minimum

the units to be bled and isolates as much of the normal

system from the emergency system as possible. In

some installations, the shuttle valve is an integral part

of the actuating unit.

A typical shuttle valve is shown in figure 8-15.

The body contains three ports-the normal system

inlet port, the emergency system inlet port, and the

unit outlet port. A shuttle valve used to operate more

than one actuating cylinder may contain additional

unit outlet ports.

Enclosed in the body is a sliding part called the

shuttle. It is used to seal one of the two inlet ports. A

8-18