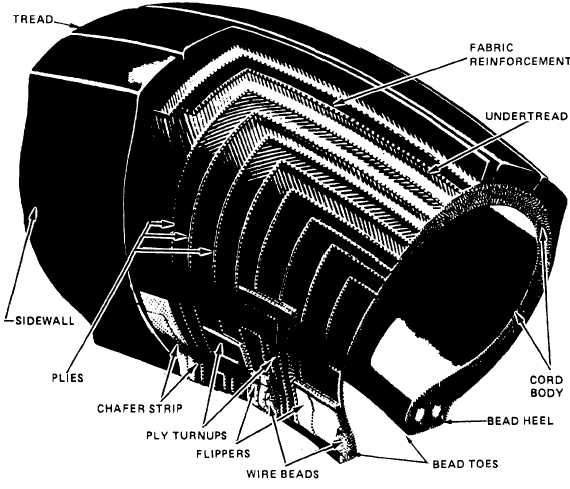

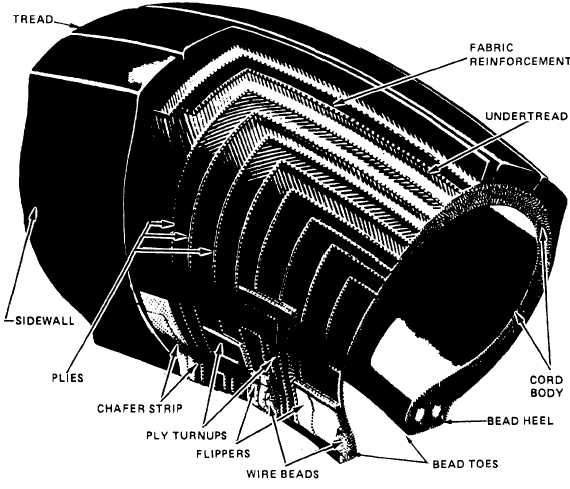

Figure 11-10.–Sectional view of aircraft tire showing construction details.

The sidewall is an outer layer of rubber adjoining

the tread and extending to the beads. Like the tread, it

protects the cord body from abrasion, cuts, bruises,

and moisture.

The beads are multiple strands of high-tensile

strength steel wire imbedded in robber and wrapped

in strips of open weave fabric. The beads hold the tire

firmly on the rims and serve as an anchor for the

fabric plies that are turned up around the bead wires.

The chafing strips are one or more plies of

rubber-impregnated woven fabric wrapped around the

outside of the beads. They provide additional rigidity

to the bead and prevent the metal wheel rim from

chafing the tire. Tubeless tires have an additional ply

of rubber over the chafing strips to function as an air

seal.

The breakers are one or more plies of cord or

woven fabric impregnated with rubber. They are used

between the tread rubber and the cord body to provide

extra reinforcement to prevent bruise damage

tire. Breakers are not part of the cord body.

Tread Patterns

to the

There are three tread patterns or tread designs

used on naval aircraft. They are plain, ribbed, and

nonskid. A plain tread has a smooth, uninterrupted

surface. A ribbed tread has three or more continuous

circumferential ribs separated by grooves. A nonskid

tread is any grooved or ribbed tread. Other tread

designs may be provided under specific circum-

stances or as required by applicable MS standards or

drawing.

The most common

aircraft is the ribbed pattern.

Tread Construction

design used on naval

The tread construction will usually be one of four

types. Other tread types may be necessary for

11-11