However, the following restrictions apply to all

sealant applications:

• Sealant should be used within the application

time limits specified by the sealant manufacturer.

• Sealant should not be applied to metal that is

colder than 70°F. Better adhesion is obtained and the

applied sealant will have less tendency to flow while

curing if the metal is warmed to a temperature

between 90°F and 100°F before the sealant is applied.

• Sealant should be discarded immediately when

it becomes too stiff to apply or work. Stiff or partially

cured sealant will not wet the surface to which it is to

be applied as well as fresh material and,

consequently, will not have satisfactory adhesion.

• Sealant should not be used for faying surface

applications unless it has just been removed from

refrigerated storage or freshly mixed.

While the use of sealants on aircraft surfaces has

greatly increased over the past few years, application

methods have been mostly through the use of

brushes, dipping, injection guns, and spatulas. The

spraying of sealants is a recent development. MIL-S-

81733 sealant, type III, is extensively used for spray

application. If type III sealant cannot be procured,

MIL-S-8802 sealant, class A, may be used by thinning

it to a sprayable consistency by the addition of an

appropriate solvent.

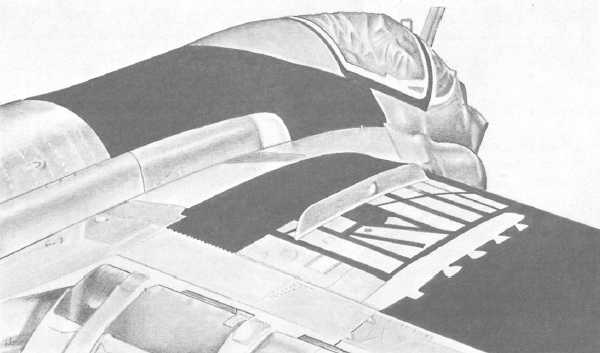

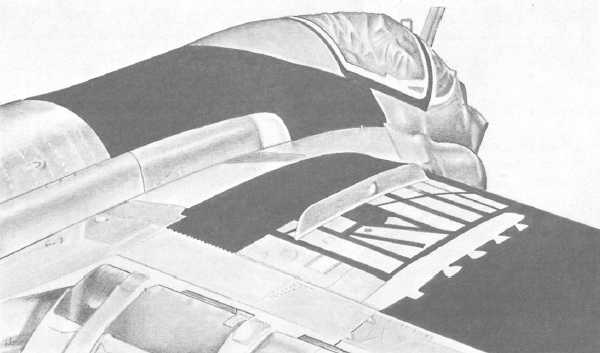

Figure 14-44 shows sealant applied to an aircraft

to protect some of the most corrosion-prone areas.

The sealant was applied using spray, spatula, and

brush methods.

When you are pressure sealing an aircraft, the

sealing materials should be applied to produce a

continuous bead, film, or fillet over the sealed area.

Air bubbles, voids, metal chips, or oily contamination

will prevent an effective seal. Therefore, the success

of the sealing operation depends upon the cleanliness

of the area and the careful application of the sealant

materials.

There are various methods of pressure sealing the

joints and seams in aircraft. The applicable structural

repair manual will specify the method to be used in

each application.

The sealing of a faying surface is accomplished by

brush coating the contacting surfaces with the

specified sealant. The sealant should be applied

immediately before fastening the parts together.

217.204

Figure 14-44.—Sealant applied to aircraft exterior surfaces.

14-46