Careful planning is necessary to close faying

surface seals on large assemblies within the

application time limit of the sealant. Once the sealant

has been applied, the parts must be joined, the

required number of bolts must be torqued, and all the

rivets driven within this time limit.

When insulating tape has been installed between

the faying surfaces to prevent dissimilar metals

contacts, pressure sealing should be accomplished by

fillet sealing. Fillet sealing is the spreading of sealant

along the seam with a sealant injection gun. The

sealant should be spread in approximately 3-foot

increments.

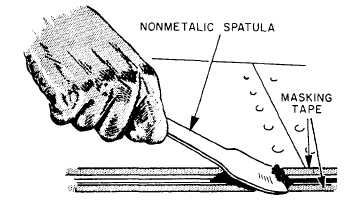

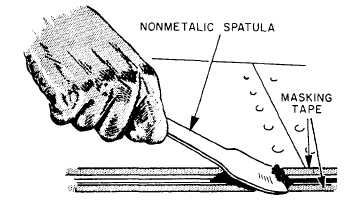

Before you proceed to the next

increment, the applied portion of the fillet should

be worked with a sealant spatula or tool. See

figure 14-45. This working of the sealant fills the

voids in the seam and eliminates air bubbles. The

leak-free service life of the sealant is determined by

the thoroughness and care you use in working out the

air bubbles.

After the sealant has cured to a tack-free

condition, the fillet should be inspected for any

remaining air bubbles.

Such air bubbles should be

opened and filled with sealant.

When a heavy fillet is required, it should be

applied in layers. The top layer should fair with the

metal.

Injection sealing is the pressure filling of

openings or voids with a sealant injection gun.

Joggles should be tilled by forcing sealant into the

opening until it emerges from the opposite side.

Voids and cavities are filled by starting with the

nozzle of the sealant injection gun at the bottom of the

space and filling as the nozzle is withdrawn.

Figure 14-45.—Applylng sealant.

NOTE: A joggle is a joint between two

pieces of material formed by a notch and a

fitted projection.

Rivets, rivnuts, screws, and small bolts should

have a brush coat of sealant over the protruding

portion on the pressure side. Washers should have a

brush coat of sealant on both sides. Split grommets

should have sealant brushed into the split prior to

installation. After installation, fillets should be

applied to both the base of the grommet and the

protruding tube in the pressure side.

Sealing Compound MIL-S-8802

This temperature-resistant, two-component,

synthetic rubber compound is used for sealing and

repairing fuel tanks and fuel cell cavities. This

compound is designed for an operating environment

that may vary between -65°F and +250°F. It is

produced in the following classifications:

Class A —Sealing material suitable for brush

application

Class

B—Sealing

material

suitable

for

application by extrusion gun and

spatula

Class C — Sealing material suitable for faying

surface sealing

Dash numbers after the classification code

indicate the allowed application time in hours before

the curing cycle will have progressed to the point

where it is no longer feasible to apply that particular

batch of sealant. Class A dash numbers are –1/2 and

–2. Class B dash numbers are –1/2, –2, and –4.

Class C dash numbers are –20 and –80 (8 hours of

application time with the remaining time allowed for

working the material).

Example: Class A-2 designates a brushable

material having an application time of 2 hours. Class

B-1/2 designates an extrusion gun material having an

application time of 1/2 hour. Class C-20 designates a

faying surface sealant with an application time of

8 hours and a working life of 20 hours.

Sealing Compound MIL-S-81733

This accelerated, room temperature, curing

synthetic rubber compound is used in sealing metal

components on weapons and aircraft systems for

protection against corrosion. This sealant contains

14-47