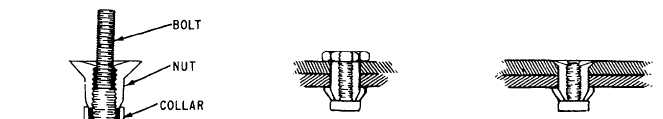

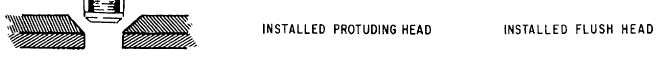

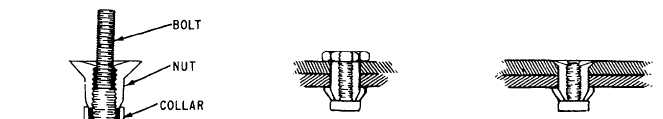

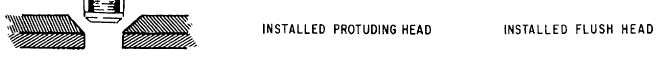

Figure 2-7.—Hi-lok fastener.

cadmium-plated alloy steel with protruding or

100-degree flush heads. Collars for the pins are made

of anodized 2024-T6 aluminum or stainless steel.

The threaded end of the pin is recessed with a

hexagon socket to allow installation from one side.

The major diameter of the threaded part of the pin has

been truncated (cut undersize) to accommodate a

0.004-inch maximum interference-free fit. One end

of the collar is internally recessed with a 1/16-inch,

built-in variation that automatically provides for

variable material thickness without the use of washers

and without fastener preload changes. The other end

of the collar has a torque-off wrenching device that

controls a predetermined residual tension of preload

(10%) in the fastener.

Jo-Bolt Fasteners

The jo-bolt, shown in figure 2-8, is a high-

strength, blind structural fastener that is used on

difficult riveting jobs when access to one side of the

work is impossible.

The jo-bolt consists of three

factory-assembled parts: an aluminum alloy or alloy

steel nut, a threaded alloy steel bolt, and a

corrosion-resistant steel sleeve.

The head styles

available for jo-bolts are the 100-degree flush head,

the hexagon protruding head, and the 100-degree

flush millable head.

Turnlock Fasteners

Turnlock fasteners are used to secure panels that

require frequent removal. These fasteners are

available in several different styles and are usually

referred to by the manufacturer’s trade name.

CAMLOC FASTENERS.—The 4002 series

Camloc fastener consists of four principal parts: the

receptacle, the grommet, the retaining ring, and the

Figure 2-8.—Jo-bolt.

2-5