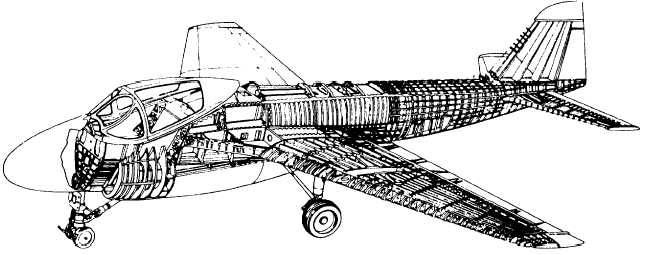

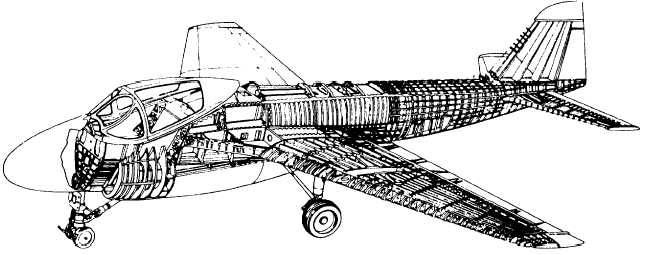

Figure 1-1.—Semimonocoque fuselage construction.

The semimonocoque fuselage is constructed

primarily of aluminum alloy; however, on newer aircraft

graphite epoxy composite material is often used. Steel

and titanium are found in areas subject to high

temperatures. Primary bending loads are absorbed by

the "longerons," which usually extend across several

points of support. The longerons are supplemented by

other longitudinal members, called “stringers.”

Stringers are lighter in weight and are used more

extensively than longerons. The vertical structural

members are referred to as “bulkheads, frames, and

formers.” These vertical members are grouped at

intervals to carry concentrated loads and at points where

fittings are used to attach other units, such as the wings,

engines, and stabilizers. Figure 1-1 shows a modified

form of the monocoque design used in combat aircraft.

The skin is attached to the longerons, bulkheads, and

other structural members and carries part of the load.

Skin thickness varies with the loads carried and the

stresses supported.

There are many advantages in the use of the

semimonocoque fuselage. The bulkheads, frames,

stringers, and longerons aid in the construction of a

streamlined fuselage. They also add to the strength and

rigidity of the structure. The main advantage of this

design is that it does not depend only on a few members

for strength and rigidity. All structural members aid in

the strength of the fuselage. This means that a

semimonocoque fuselage may withstand considerable

damage and still remain strong enough to hold together.

On fighters and other small aircraft, fuselages are

usually constructed in two or more sections. Larger

aircraft may be constructed in as many as six sections.

Various points on the fuselage are heated by station

number. Station 0 (zero) is usually located at or near the

nose of the aircraft. The other fuselage stations (FS) are

located at distances measured in inches aft of station 0.

A typical station diagram is shown in figure 1-2. On this

particular aircraft, station 0 is located 93.0 inches

forward of the nose.

Quick access to the accessories and other equipment

carried in the fuselage is through numerous doors,

inspection panels, wheel wells, and other openings.

Servicing diagrams showing the arrangement of

equipment and the location of access doors are supplied

by the manufacturer in the maintenance instruction

manuals and maintenance requirement cards for each

model or type of aircraft. Figure 1-3 shows the access

doors and inspection panels for a typical aircraft.

ENGINE MOUNTS

Engine mounts are designed to meet particular

conditions of installations, such as their location on the

aircraft; methods of attachment; and size, type, and

characteristics of the engine they are intended to

support. Although engine mounts vary widely in their

appearance and in the arrangement of their members,

the basic features of their construction are similar. hey

are usually constructed as a single unit that may be

detached quickly and easily from the remaining

structure. In many cases, they are removed as a complete

1-2