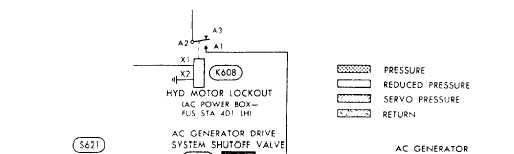

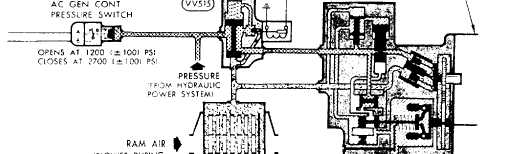

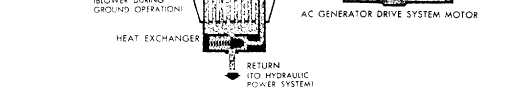

Figure 12-64.—AC generator drive system.

with approved metal closures. Repaired components

that are to be installed immediately subsequent to bench

testing should be drip-drained, capped, and plugged as

neccessary. Plastic plugs are prohibited because of the

possibility of plastic chips entering the component and

damaging seals or blocking critical passages.

The man-hours expended in correcting mal-

functions are documented on a VIDS/MAF. When apart

is removed and is to be processed through the IMA for

repairs, an additional VIDS/MAF is initiated with the

appropriate information tilled in and attached to the

component for turn-in. Consult the appropriate manuals

for proper documentation of the VIDS/MAF. The job is

not considered complete until the necessary paperwork

has been completed screened, and turned in.

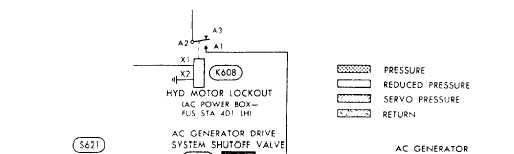

GENERATOR DRIVE SYSTEM

(HYDRAULICALLY OPERATED)

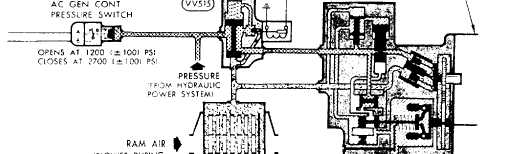

The ac generator drive system shown in figure

12-64 is hydraulically operated by pressure from the

hydraulic power system. The AC GEN switch on the

copilot’s sub-instrument panel operates the shutoff

valve that controls the generator drive system. The

system consists of a shutoff valve, a hydraulically driven

motor a heat exchanger, a control switch, and a relay.

During normal aircraft operation and with the AC

GEN switch at OFF, the solenoid-operated shutoff valve

is energized (closed). The hydraulic motor lockout relay

is also energized. Under this condition, the generator

does not operate, since hydraulic pressure is stopped at

the shutoff valve. When the AC GEN switch is moved

to ON, the hydraulic motor lockout relay and the shutoff

valve is de-energized and the valve opens. Hydraulic

fluid at 3,000 psi is directed to operate the constant speed

variable displacement motor at 8,000 RPM. When the

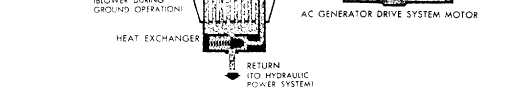

fluid exits from the motor into the return lines, it is

routed through a heat exchanger and ram air cooled

before returning to the power system reservoir. When

ram air is not available on the deck, an electrically driven

blower is engaged automatically to provide airflow.

Maintenance of the generator drive system

normally consists of servicing, testing and checking for

proper operation, adjusting, troubleshooting, and

removal and installation of system components, flexible

line couplings, and other plumbing. Servicing and

maintenance procedures and precautions are listed in the

MIM and respective (03) overhaul manuals and must be

observed at all times to complete the procedures

efficiently and safely. Particular attention should be

12-74