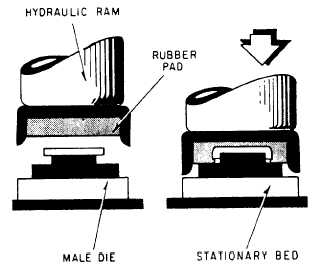

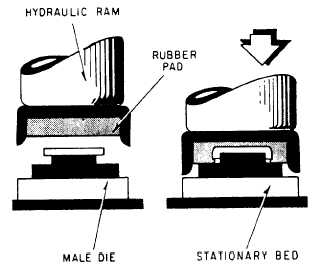

Figure 1-24.—Guerin process.

easily; precautions must be taken to avoid this if

possible. If they are ignited, you should extinguish them

immediate y with an extinguishing powder such as

powdered soapstone, clean, dry, unrusted cast iron

chips, or graphite powder.

Water or any

CAUTION

standard liquid or foam

extinguisher causes magnesium to burn more

rapidly and may cause small explosions.

SUBSTITUTION AND

INTERCHANGEABILITY

OF AIRCRAFT METALS

In selecting interchangeable or substitute materials

for the repair and maintenance of naval aircraft, it is

important that you check the appropriate aeronautic

technical publications when specified materials are not

in stock or not obtainable from another source. It is

impossible to determine if another material is as strong

as the original by mere observation. There are four

requirements that you must keep in mind in this

selection. The first and most important of these is

maintaining the original strength of the structure. The

other three are maintaining contour or aerodynamic

smoothness, maintaining original weight, if possible, or

keeping added weight to a minimum, and maintaining

the original corrosive-resistant properties of the metal.

Because different manufacturers design structural

members to meet various load requirements, you can

appreciate the importance of checking the specific

technical publication. Structural repair of these

members, apparently similar in construction, will thus

vary in their load-carrying design with different aircraft.

Structural repair instructions, including tables of

interchangeability and substitution for ferrous and

nonferrous metals and their specifications for all types

of aircraft used by the Navy, are normally prepared by

the contractor. Such instructions are usually contained

in the NA 01-XXX-3 manual covering structural repair

instructions for specific models of aircraft. Similar

information is also contained in General Manual for

Structural Repair, NA 01-1A-1.

Aerospace Metals-General Data and Usage

Factors, NA 01-1A-9, provides precise data on specific

metals to assist in selection, usage, and processing for

fabrication and repair.

Always consult these publications and the NA

01-XXX-3 aircraft manual for the specific type of

aircraft when confronted with a problem concerning

maintenance and repair involving substitution and

interchangeability of aircraft structural metals. Be sure

you have the most recent issue of the aeronautic

technical publication.

HARDNESS TESTING

Learning Objective: Recognize hardness

testing methods, related equipments, and their

operation

Hardness testing is a method of determining the

results of heat treatment as well as the state of a metal

prior to heat treatment. Since hardness values can be tied

in with tensile strength values and, in part, with wear

resistance, hardness tests are an invaluable check of

heat-treatment control and of material properties.

Practically all hardness testing equipments now in

service use the resistance to penetration as a measure of

hardness. Included among the better known bench-type

hardness testers are the Brinell and the Rockwell, both

of which are described and illustrated in this section.

Also included are three portable type hardness testers

now being used by maintenance activities.

1-35