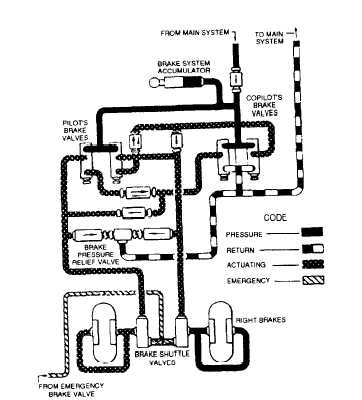

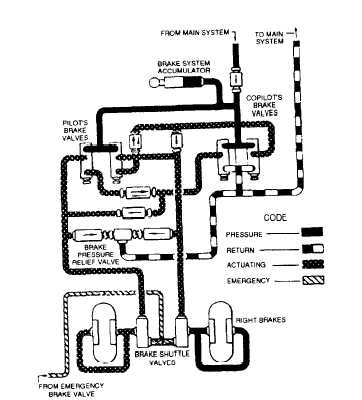

Figure 12-26.-Typical power brake control valve system.

When the brake pedals are released, the main

system pressure port in the master cylinder is closed off,

and fluid is forced out the return port, through the return

line to the brake reservoir. The brake reservoir is

connected to the main hydraulic system reservoir to

assure an adequate supply of fluid to operate the brakes.

When the emergency air system is used, air

pressure, directed through a separate set of lines, acts on

the shuttle valves, blocking off the hydraulic lines and

actuating the brakes.

POWER BRAKE CONTROL

VALVE SYSTEM

A power brake control valve system is used on

aircraft requiring a large volume of fluid to operate the

brakes. As a general rule, this applies to all patrol (VP)

and reconnaissance (VR) aircraft, and certain attack

(VA) aircraft. Because of the weight and size of the

aircraft, large wheels and brakes are required. Larger

brakes mean greater fluid displacement and higher

pressures. For this reason, independent master cylinder

type of systems are not practical on heavy aircraft. A

typical power brake control valve system is shown in

figure 12-26.

In this system, a line is tapped off from the main

hydraulic system pressure line. The first unit in this line

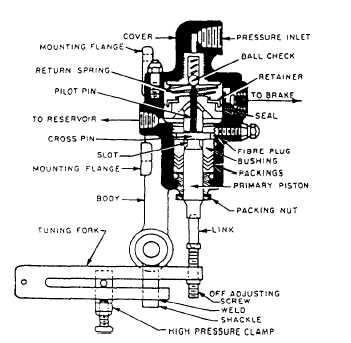

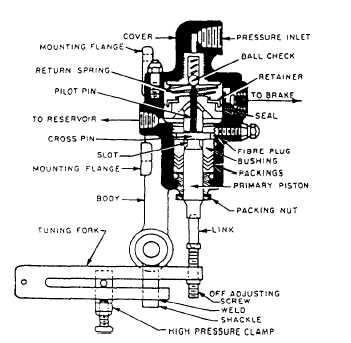

Figure 12-27.-Power brake control valve (pressure ball check

type).

is a check valve, which prevents loss of brake system

pressure in case of main system failure.

The next unit is the accumulator, the main purpose

of which is to store a reserve supply of fluid under

pressure. When the brakes are applied and pressure

drops in the accumulator, more fluid enters from the

main system and is trapped by the check valve. The

accumulator also acts as a surge chamber for excessive

loads imposed upon the brake hydraulic system.

Following the accumulator are the pilot’s and

copilot’s brake valves. The purpose of a brake valve is

to regulate and control the volume and pressure of the

fluid that actuates the brake.

Four check valves and two one-way restrictors,

sometimes referred to as orifice check valves, are

installed in the pilot’s and copilot’s brake actuating lines.

The check valves allow the flow of fluid in one direction

only. The orifice check valves allow unrestricted flow

of fluid in one direction, from the pilot’s brake valve;

flow in the opposite direction is restricted by an orifice

in the poppet. The purpose of the orifice check valves is

to help prevent chatter.

The next unit in the brake actuating lines is the

pressure relief valve. In this particular system, the

pressure relief valve is preset to open at 825 psi to

discharge fluid into the return line. The valve closes at

760 psi minimum.

Each brake actuating line incorporates a shuttle

valve for the purpose of isolating the emergency brake

12-32