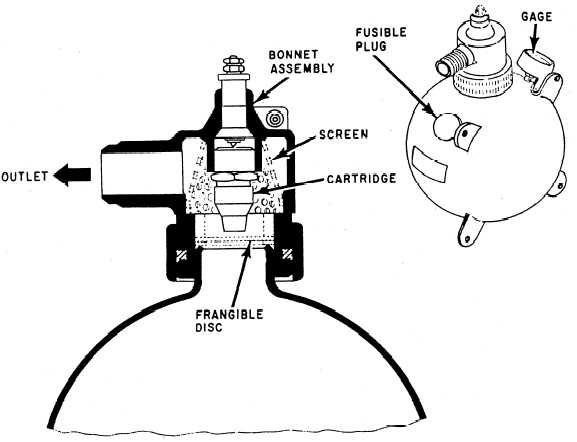

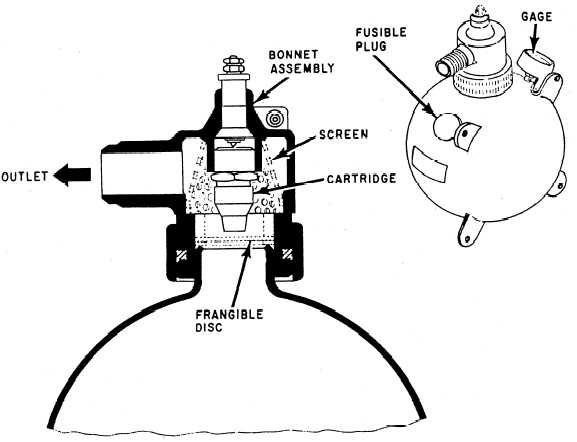

engine nacelle. A screen in the bonnet (fig. 1-24)

prevents the segments of the shattered disc from

being expelled into the distributing assembly. The

CF3Br agent discharges from the distributing

assembly as a spray, which (in the presence of

heat) turns into a dense gas. This gas reduces the

oxygen supply content of the area and effectively

smothers the fire.

Container Assembly

Each container assembly (fig. 1-24) consists

of the following components: A fusible plug,

pressure gage, frangible disc, cartridge, bonnet,

and the container itself. The container is a

spherical assembly, designed to contain 6.5

pounds of CF3Br and a precharge of 600 psi of

nitrogen at (70°F).

NOTE: The capacity and precharge of the

container assembly will vary with the type of

installation.

Figure 1-24.—CF3Br container assembly.

The combined nitrogen charge and CF3Br is

retained in the container by the frangible disc and

the fusible plug. The fusible plug protects the

container from possible damage by excess pressure

caused by an increase in ambient temperature. The

metal of the fusible plug melts at temperatures

between 208° and 220°F, releasing the contents

of the container overboard.

Discharge Indicator

One discharge indicator is mounted on each

nacelle as shown in figure 1-23. The indicator

consists of a red disc and an aluminum alloy tube

that connects to the container at the fusible plug.

If thermal expansion in the container is great

enough to rupture the fusible disc, the red disc

will rupture and the CF3Br will flow overboard

through the line to the indicator. Therefore, when

the discharge indicator is missing, the container

must be checked for proper pressure.

Some CF3Br containers have a relief valve in

place of the fusible plug. On some, the fusible

1-33