Electrically Actuated Canopy Seal

An electrically actuated canopy pressure seal

system is shown in figure 2-11. This type of system

is controlled by a pressure regulator and dump

valve assembly, which consists of a pressure

regulator, a solenoid poppet shutoff and vent

valve, and a relief valve.

Electrically Actuated Canopy

Pressure Seal Regulator Valve

The canopy pressure seal regulator valve

controls the pressurizing and depressurizing of the

canopy seal, depending upon the canopy position.

The pressure regulator consists of a spring-loaded

diaphragm, which controls a poppet valve to

admit the correct air pressure to the canopy seal.

An adjustment screw is provided at the top of the

regulator housing to adjust the output of air

pressure.

The shutoff and dump valve consists of a

solenoid-operated poppet valve, which is spring-

loaded to the closed position. When the solenoid

is energized (fig. 2-11, view A), the dump valve

closes the vent port and opens the regulator

shutoff to permit inflation of the canopy seal. The

outlet pressure is maintained at approximately 20

psi by the pressure regulator.

When the solenoid is de-energized by the

opening of the canopy (fig. 2-11, view B), the

dump valve opens the vent port, closes the

regulator shutoff to stop the flow of supply air,

and dumps the pressure in the canopy seal over-

board through the vent line. The relief valve

feature of the pressure regulator prevents seal

pressure from becoming excessive during rapid

altitude changes by venting the seal pressure over-

board when the pressure reaches a maximum of

22 psi (fig. 2-11, view C).

In case of an electrical failure, the reg-

ulator valve is spring-loaded in the dump

position.

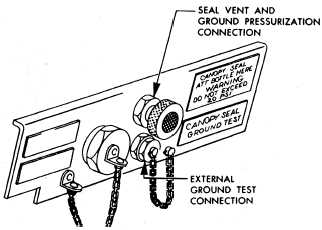

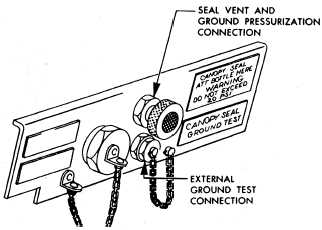

Ground Test Connections

Most canopy pressure seal systems have

ground test connections that are used to

ground test the system and to pressurize

the system during carrier deck storage. The

Figure 2-12.—Cabin air pressure test panel.

ground test connections (fig. 2-12) are usually

located on the cabin air pressure test panel.

One connection is used for ground test, and

the other, which is normally the seal vent,

is used for ground pressurization of the canopy

seal.

MAINTENANCE

Maintenance of the canopy system consists of

servicing, troubleshooting, and removal and

installation of components. The applicable air-

craft maintenance instructions manual (MIM)

furnishes such information as proper procedure,

manpower requirements, materials lists, tool and

equipment lists, quality assurance instructions,

and maintenance-level instructions for the disposi-

tion of defective parts.

Servicing

Servicing is limited to cleaning the canopy seal,

ground inflating the canopy seal, and periodic

inspections for visible defects, dirt, and foreign

material accumulations. All major components

of the system are self-sustaining and require no

general servicing between overhaul periods for

normal operation.

When pressurized aircraft are stowed on

the carrier flight deck without canopy covers,

the canopy seal should be inflated externally

to protect the cabin area. Ground pressurization

of the canopy seal is accomplished by attaching

an external air source to the canopy seal

vent and ground pressurization connection

2-15