and maintains a maximum of 9 to 11 psi in the

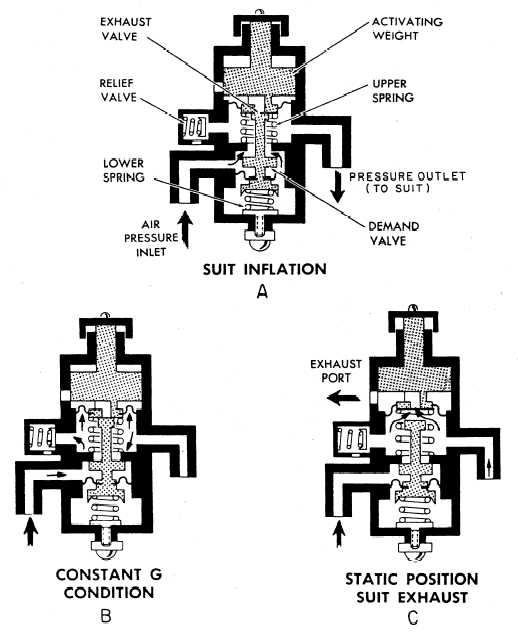

valve outlet chamber. Figure 1-4 illustrates the

operation of the single-stage anti-g valve.

When a force of approximately 1.5 g’s is

exerted on the aircraft, the activating weight over-

comes the upper spring tension and closes the

exhaust valve (fig. 1-4, view A). As the weight

travels downward, it further depresses the valve

assembly, forcing the demand valve from its seat,

thus overriding the pressure of the lower spring

and opening the demand valve. Air pressure then

flows past the open demand valve, through the

valve outlet into the valve outlet line, through the

suit quick disconnect, and into the anti-g suit.

As the g forces being applied to the aircraft

are stabilized and become constant, the pressure

under the activating weight diaphragm builds up

sufficiently to lift the weight and to reduce the

pressure on the valve assembly enough to close

the demand valve (fig. 1-4, view B). The demand

valve closes under pressure of the heavier lower

spring, while the exhaust valve remains closed by

the activating weight. The suit pressure is then

trapped in the pressure outlet chamber of the

Figure 1-4.—Anti-g valve operation (single stage).

1-4