The volume of any gas compressed in a cylinder

is directly proportional to the pressure. If the

pressure is half, the volume is half, etc. Therefore,

if 900 psi of oxygen remains in an 1,800 psi

system, half the oxygen is left.

A pressure gauge is always mounted at each

flight station, usually on the regulator. These

gauges are calibrated to indicate from 0 to 2,000

psi on high-pressure systems and 0 to 500 psi on

reduced high-pressure systems.

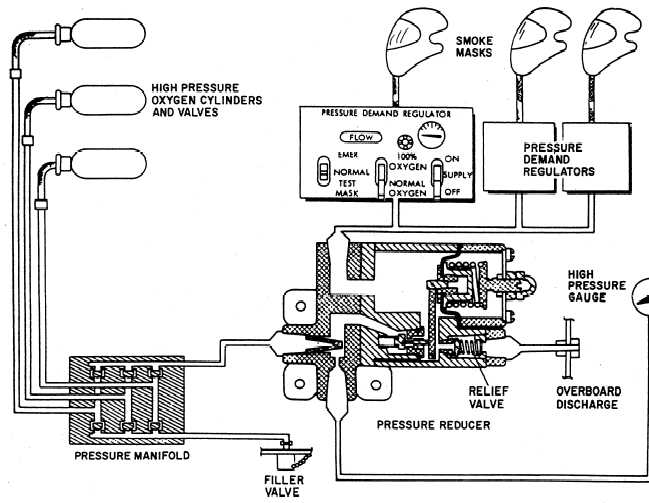

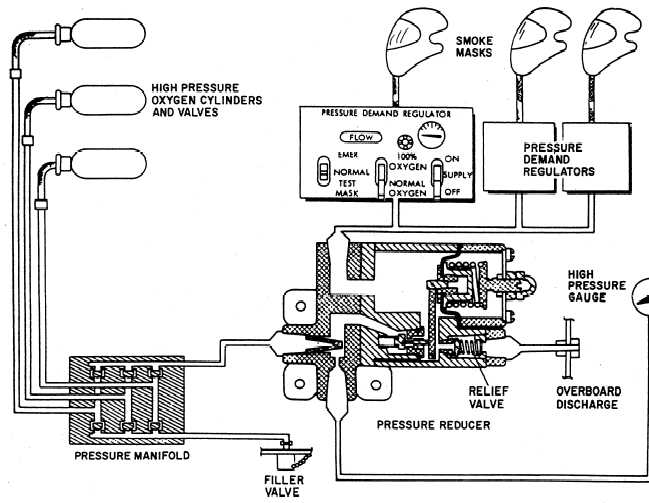

TYPICAL GASEOUS

OXYGEN SYSTEMS

As previously stated, naval aircraft equipped

with high-pressure oxygen systems are designed

for approximately 1,800 psi, and working

pressures reduce to 60 to 70 psi by a reducer or

regulator. Systems equipped with pressure

reducers are referred to as reduced high-pressure

systems. The reduced high-pressure gaseous

oxygen system shown in figure 4-5 is typical of

such systems. Oxygen is stored in three high-

-pressure cylinders and supplies three regulators—

one each for the pilot, copilot, and flight engineer.

SYSTEM OPERATION

The pressure manifold, which is equipped with

internal check valves, receives oxygen flow from

the cylinders, directs the flow into a common line,

and routes it to the pressure reducer. The

manifold assembly also connects to a filler line,

allowing the three cylinders to be recharged

simultaneously from an external supply. The

pressure reducer decreases the pressure to 65 psi.

Incorporated on the low-pressure side of the

pressure reducer is a relief valve, which connects

Figure 4-5.—Reduced high-pressure oxygen system schematic,

4-8