contact area of the tire, causing it to wear faster at the

tread center. Failure due to carcass ruptures and breaks

in the tire cords that result from contact with foreign

objects are usually caused by overinflation.

Underinflation increases the contact area and causes

the tire to wear rapidly and unevenly at the outer edges

of the tread. An underinflated tire flexes excessively

and develops high temperatures that weaken tire cords.

An underinflated tire also may slip on the wheel during

landing and shear off the valve stem.

To determine the proper inflation pressure, you

should check an inflation chart like the one shown in

figure 5-6. If the gross weight of an aircraft is 20,000

pounds, the correct tire pressure for that aircraft when

shore based is 310 psi. If the aircraft is carrier based,

the pressure is maintained at 350 psi, regardless of the

gross weight. When aircraft tire pressure is low, you

should add air from a regulated source.

CAUTION

An unregulated, high-pressure air source

for tire inflation is a hazard. Tire inflation

source pressure should be carefully moni-

tored. If high-pressure cylinders (such as the

portable air bottle or the air or nitrogen serv-

icing trailer) are used, a regulator must be

used to prevent inadvertent overinflation.

Maintenance personnel must always use a remote

inflator unit when inflating tires. The operator of this

unit should always stand at right angles to the landing

gear axle, directly in front or in the rear of the tire. The

operator should also stand at the full length of the

inflator unit hose. This will prevent the operator from

being struck by pieces of the wheel if it were to fail

CAUTION

When an aircraft wheel is to be removed

from the aircraft, maintenance personnel must

deflate the tire before removing the wheel

assembly from the aircraft. This precaution is

necessary because of the possibility that the

bolts in split-type wheels might have been

sheared during landing, causing the wheel

halves to separate when the axle nut is re-

moved. Personnel have been killed because

they failed to remove the air from the tire

before removing the axle nut.

Oxygen Servicing

Plane captains are responsible for making sure that

the liquid oxygen systems of the aircraft are serviced.

Personnel in the Aviation Structural Mechanic, Safety

Equipment, (AME) rating refill these converters.

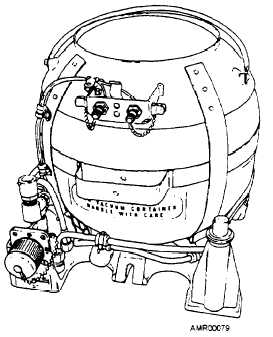

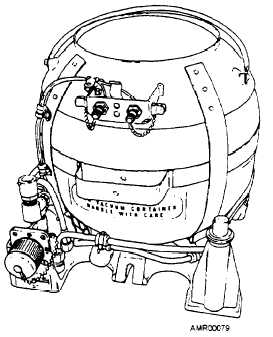

A typical liquid oxygen converter is shown in

figure 5-7. Liquid oxygen is dangerous to handle and

requires special handling procedures. These special

handling procedures are discussed later in this chapter.

SERVICING EQUIPMENT

The following text discusses the equipment used

to service aircraft, such as the high pressure air valve,

servicing trailers, preoiler hand pumps, and fluid

service unit HSU-1.

High-Pressure Air Valve

The high-pressure air valve is used to service

struts, accumulators, air storage bottles, and other

components serviced with high-pressure air. The

high-pressure air valve, shown in figure 5-8, is used

on most naval aircraft. It is referred to by its military

specification (MS) number MS 28889-1. Air valve MS

28889-1 does not have a valve core.

When servicing a system equipped with a

high-pressure air valve, you should exercise extreme

Figure 5-7.—Typical liquid oxygen converter.

5-12