A pressure drop on the regulated low-pressure

gage indicates that the leakage on/off valve is

leaking. This completes your leakage check. You

must bleed the system by turning the high-pressure

regulator to the VENT position until the high-

-pressure gage reads zero and then open the system

bleed valve. This bleeds all remaining lines.

REGULATED LOW-PRESSURE

NITROGEN SYSTEM

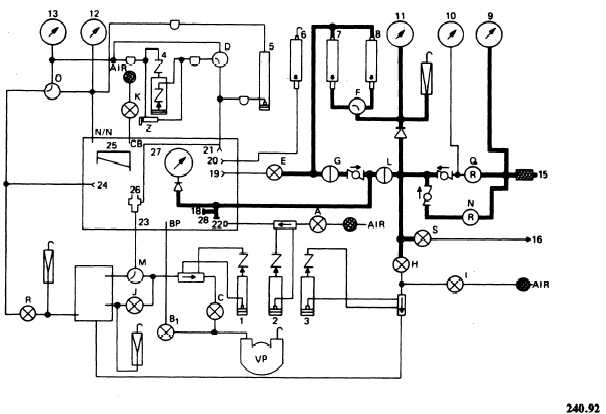

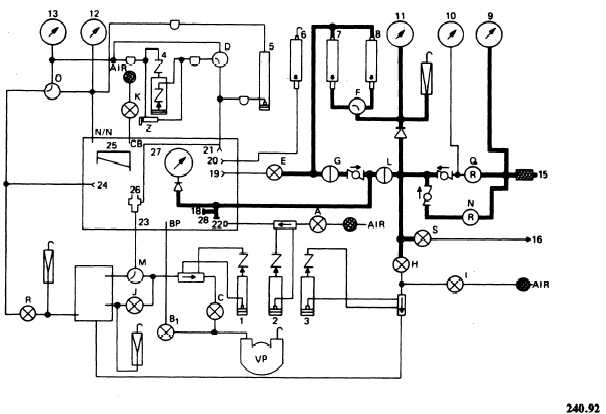

The purpose of the regulated low-pressure

nitrogen system is to supply regulated low-

pressure nitrogen to the N2 input connection and

the in-system leakage rotameters. This system,

shown in figure 2-5, has a range of 0 to 180 psig.

You adjust the pressure by using the mechanically

operated low-pressure regulator. When you open

the low-pressure regulator, nitrogen flows through

the one-way check valve to the back side of the

one-way check valve that protects the high-

-pressure regulator.

A s n i t r o g e n e n t e r s t he

high-pressure lines, it flows to the inlet pressure

on/off valve, the system’s bleed valve, the vent

pressure valve, and through the gage guard that

protects the in-systems leakage rotameters.

(Nitrogen also flows into the rotameters and to

the 200- to 230-psig relief valve. However, this

is not considered part of the low-pressure system.

For the nitrogen to flow to the item under test,

you have to open the inlet pressure on/off valve.

T h i s a l l o w s n i t r o g e n t o f l o w t o t h e i n p ut

connection inside the chamber where the item

under test is connected.

PRESSURIZING THE REGULATED

LOW-PRESSURE NITROGEN SYSTEM

When you pressurize the low-pressure nitrogen

system, be sure that the N2 input connection is

capped and the supply cylinder valve is open. Turn

the leakage selector valve to the HIGH position

and the pressure selector valve to the HG

position. Turn the inlet pressure and leakage

on/off valves to the ON position. Slowly turn the

l o w - p r e s s u r e r e g u l a t o r c l o c k w i s e u n t i l t he

regulated low-pressure gage and the N2 input gage

indicate 70 psig. (We use 70 psig because this is

the pressure used to calibrate the rotameter

system.) At this time, return the inlet pressure

on/off valve to OFF. There should be no leakage;

but if any leakage occurs, the small ball in the

high-range leakage rotameter tube will rise.

Figure 2-5.—Model 1172AS100 regulated low pressure N2 system.

2-6