effective job can be done by disassembling the

shears and sharpening one shear at a time. The

bottom shear has a more blunt angle than the

upper, so exercise care in the cutback or angle of

sharpening. Also in sharpening, start at the point

or toe of the shear and move toward the heel of

the shear. This drives the heat, generated in

grinding, to the heel of the shear where there is

more metal to radiate the heat. To grind toward

the toe or point drives the heat to the lesser metal,

and it can result in burning the metal and drawing

the temper out.

After grinding the shear,

reassemble it loosely at first so that, on the first

closing, the wire edge resulting from the grinding

is removed.

Another type of shears you will use is known

as pinking shears. This tool is used for cutting a

series of Vs along fabric edges to prevent fraying.

If pinking shears become dull, they should be

returned to the manufacturer for sharpening.

Remember, always keep the shears sharp.

Don’t drop your shears, as this springs the blades

and reduces their cutting ability. DON’T use them

to puncture metal objects or to pry things open.

DON’T use shears as a knife to remove stitching;

you may injure yourself or damage the stitches

you are cutting. (For this job, use an upholsterer’s

knife or a stitch cutting tool.) When shears are

beyond shop maintenance capabilities, return

them to supply for a replacement.

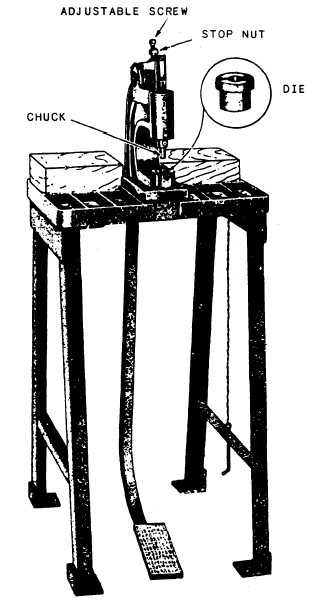

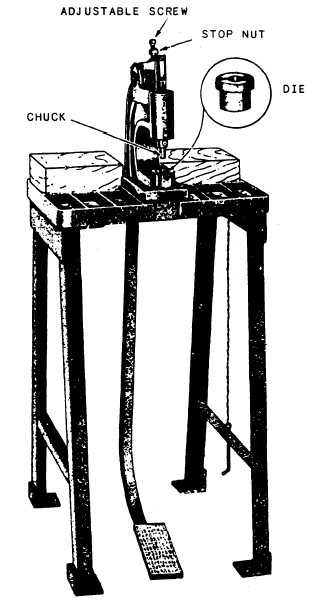

FOOT-OPERATED GROMMET PRESS

With the foot-operated grommet press, as

shown in figure 10-6, you can install grommets

by mass production. The press itself stores the two

parts of the grommet, leaving your hands free to

position material while your foot applies the

needed pressure. The important parts of this press

are the chuck and die. For each type and size of

grommet, there is a corresponding chuck and die.

The chuck is the upper tool; the die is the lower

tool. Use the adjustment screw, located either at

the top or bottom of the foot-operated press, to

prevent pressure damage to the chuck and die.

When set correctly, this adjustment screw will set

the clearance of the chuck and die to 1/32 inch,

about the thickness of bond typing paper, which

is adequate for most grommets. Some foot-

operated presses have been in service for as many

as 25 years and still require only the replacement

of the chuck and die. The foot press may also be

used in the shop to install glove fasteners.

However, if a portable glove fastener installation

tool is needed, you can use the hand press.

239.371

Figure 10-6.-Foot-operated press.

HAND PRESS

The Durable Fastener hand press, as shown

in figure 10-7, mates the two female portions of

the fastener (socket and button) and the two

female portions (stud and eyelet). You will use

this often as you replace Durable Fasteners on

soundproofing, cushions, or other related items

where a portable installations tool is required.

KNIVES

A knife, because of its familiarity, can be one

of the most abused tools. At its best, a knife has

10-10