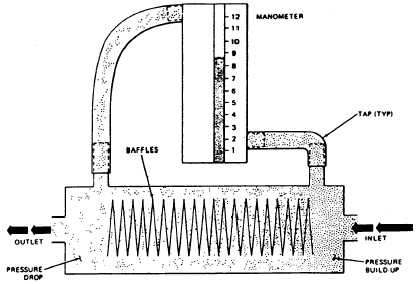

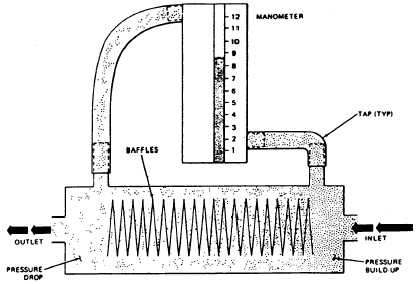

(See figure 11-2.) Baffles inside the element create

a flow restriction. As air or nitrogen enters the

element, a pressure buildup is created at the inlet

end; as it flows past the baffles, a pressure drop

occurs at the outlet end. The inlet (pressure

buildup) tap is connected to the bottom of the in-

dicating manometer, and the outlet (pressure

drop) tap is connected to the top of the

manometer. As the control valve is opened, gas

flows from the valve through the Vol-O-Flo, and

the pressure drop thus created allows the fluid in

the manometer to rise. The operator reads the

amount of flow passing through the V0l-O-Flo

on the indicating manometer.

CONTROL VALVES

A control valve regulates, or restricts, a

specified flow. Two types of control valves,

measuring and nonmeasuring, are used on the test

stand. Measuring control valves have measuring

devices (gauges or manometers) to visually

measure the flow through the valve as it is opened.

Nonmeasuring control valves have no indicating

devices. There are six measuring and three

nonmeasuring control valves on the test stand.

Measuring Control Valves

The measuring control valves (fig. 1 l-l) are

as follows:

1. The INPUT valve (A) allows a measurable

flow of air into the altitude chamber. It can only

be used during simulated altitude conditions. As

the chamber altitude increases, pressure inside the

chamber decreases, and the ambient air pressure

outside the chamber is greater. When valve (A)

is opened, air from outside the chamber flows

through valve (A); through the input Vol-O-Flo

element, indicating the amount of air flow on the

INPUT FLOW manometer (2); and through the

INPUT port (22) into the chamber.

2. The VACUUM CONTROL valve (B1) on

Model 1172AS100 allows direct evacuation of the

altitude chamber to the desired simulated altitude

by decreasing pressure in this chamber.

3. The OUTPUT valve (C), when opened,

draws a direct flow from the item under test

through the piezometer (26), OUTPUT port (23),

FLOW SELECTOR valve (M) and the output

Vol-O-Flo element to the vacuum pump. As the

flow passes through the output Vol-O-Flo, the

pressure is displayed on the OUTPUT FLOW

manometer (1).

4. The LEAKAGE CONTROL valve (E)

controls the flow to the LOW-PRESSURE

connection (19), which is located inside the

chamber. As the name of the valve implies, it is

used to perform various leak tests on oxygen

components. When you use the LEAKAGE

CONTROL valve (E) to perform leakage tests on

components, a line with bayonet fittings must

be installed between the LOW-PRESSURE

connection (19) and the REFERENCE-TAP

connection (21 ). This allows the flow passing

Figure 11-2.—VOI-O-FIO element.

11-6

239.477