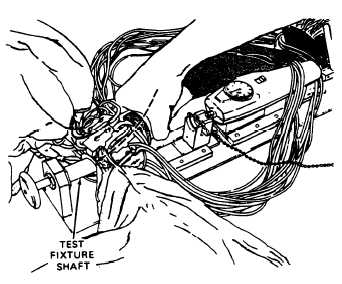

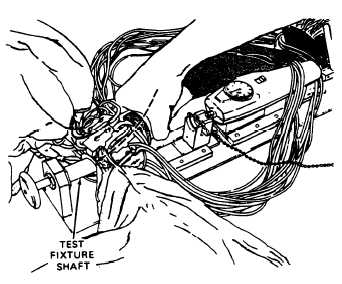

Figure 22-24.—Sliding on to test fixture.

so that the shaft butts against the bottom of the

cartridge chamber (fig. 2-24).

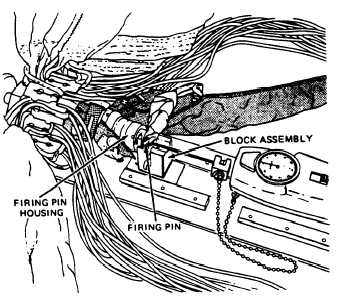

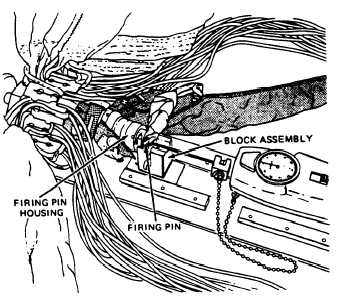

9. Open the four snap fasteners on the

spreading gun extractor sleeve to expose the firing

pin housing. Slide the block assembly at the center

of the test fixture under the firing pin housing

until the block assembly pin slides into the

baseplate hole. Align the firing pin so that the hole

in the firing pin is horizontal. The firing lanyard

is located at the top. (See figure 2-25.)

Figure 2-25.—Spreading gun installation.

10. Attach the hook assembly to the firing pin

hole, and slide the hook assembly block over the

nut that is attached to the pull gage. (See figure

2-21).

11. Move the switch on the pull gage to the

center position. You must zero your meter needle

by rotating the bezel on the dial. Move the switch

to the full down position, away from the meter,

for recording the pull force.

12. The QA verifies the test fixture lever firing

pin releases. The pull force must go between 25

and 38 pounds. If a gun has failed the first test,

it must be retested two more times. The gun must

pass both retests. Record the force required to

release the firing pin on the Parachute

Configuration, Inspection, and History Record.

When a gun fails, it is removed and returned to

supply as a defective item.

13. After the pull-force measurement has been

obtained, remove the hook assembly from the

firing gun.

14. Push the firing pin back into the housing.

Push the control disc firmly inward, forcing the

firing pin out of the housing. Apply inward hand

pressure to the firing pin as it moves out. Continue

to move the control disc inward, applying hand

pressure to the firing pin until it clicks into place.

When a click is heard, the gun is cocked. Gently

release the control disc while still exerting pressure

on the pin.

15. The QA inspector must tug gently on the

firing pin until the effect of spring loading is felt.

If the pin moves without spring tension, the gun

is not cocked, and step 14 must be repeated.

16. Release the block assembly by pulling the

pin out of the hole in the baseplate and sliding

the block away from the spreading gun. Remove

the gun from the shaft. Do not remove the gun

by pulling on the firing lanyard.

17. At this time, install the safety pin.

CAUTION

WHEN YOU ARE USING ALCOHOL

TO CLEAN THE CARTRIDGE CHAM-

BER, DO NOT ALLOW ALCOHOL TO

FLOW INSIDE THE GUN BECAUSE

THIS COULD DAMAGE THE O-RINGS

AND LUBRICATION.

2-14