FUNCTIONAL TESTING

Before you attempt to perform a functional

test, you should ensure that the work area

surrounding the preserver is free of all foreign

objects. This is done to prevent any accidental

damage to the life preserver. When you perform

a functional check, you want to ensure that the

system operates as if the aircrew member were

using it in an emergency. Therefore, your first step

is to pull the actuation toggle.

The preserver should fully inflate to its design

shape without any evidence of restriction in less

than 30 seconds. If the preserver does not meet

this requirement, you will have to determine the

reason and correct it. To do this, first look at your

stem and valve. Sometimes dirt or foreign matter

can cause a slow inflation. If you make any

corrections, the preserver is functionally tested

again.

Deflate the preserver by using a vacuum

pump and a 3/8- or 1/2-inch inside diameter

rubber hose. Attach one end of the rubber hose

to the vacuum pump, and the other end will go

to the oral inflation valve or to the carbon

dioxide cylinder valve, depending on which type

you are using. After the preserver has been

completely deflated, release the oral inflation

valve or put the CO2 cylinder back into the valve.

The functional check is only performed when

the preserver is placed into service and every

fourth calendar check after that.

LEAKAGE TEST

All life preservers are subjected to a leakage

test each calendar/phase inspection. This test is

performed each time the preserver comes into be

checked, even when a functional test is required.

A special test fixture is needed to perform this

test.

Test Fixture

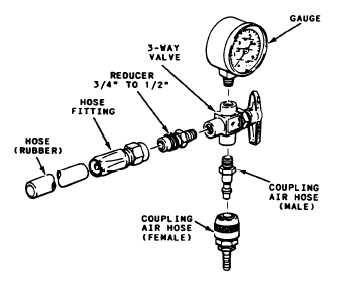

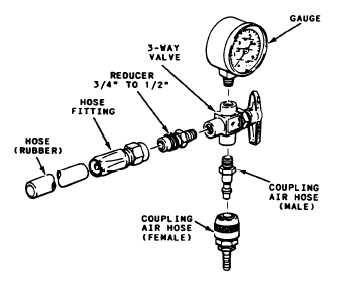

A suggested test fixture, consisting of a three-

way valve, pressure gauge, and adapters for

compartments being tested, is shown in figure

6-16. The fixture must be fabricated to meet the

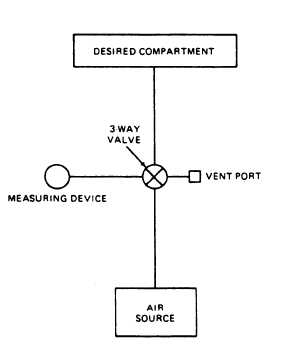

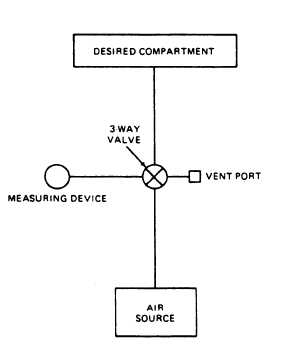

requirements of the schematic shown in figure

6-17.

239.471

Figure 6-16.—Leakage test fixture life preserver.

Figure 6-17.—Test rig schematic.

Test Procedure

To test life preservers, proceed as follows:

1. Ensure all carbon dioxide has been

removed from any preserver that has been

functionally tested.

2. To test the LPU-28/P life preserver, insert

a 3/4-inch O.D. rubber hose into the oral inflation

6-30