239.309

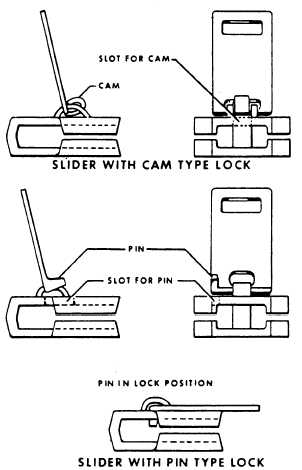

Figure 10-20.-Slide fastener pull tabs.

A brief inspection will determine whether a

slider (or pull tab) is the locking or nonlocking

type. Always be certain that the pull tab is lifted

at right angles to the slider before attempting to

remove the locking type. The relative positions

of the pull tabs are shown in figure 10-20.

Interlocking Slide Fastener Tools

In addition to common tools such as

screwdrivers, pliers, awls, knives, scissors, and

needles, a well-equipped slide fastener kit should

be included in the parachute loft equipment.

The interlocking slide fastener kit (zipper

repair kit) contains all the parts necessary to repair

any size or type of interlocking slide fastener, plus

the following special tools: end cutters, or nippers,

used for removing stops and teeth; stop-closing

pliers, specially designed to span over the slider

and clamp the stops in position; and pull-up pliers,

designed to close the slider without a pull tab.

Another handy tool in slide fastener repair is an

awl with a bent tip. This tool maybe used to close

the chain by hand.

Interlocking Slide Fastener Repair

A torn or ripped interlocking slide fastener

bead cannot be repaired, but should be replaced

with a complete new interlocking slide fastener.

If the bead is damaged near the top or bottom

of the interlocking slide fastener, and the damaged

ends can be cut off to shorten the interlocking

slide fastener without hampering the usefulness

of the garment, an effective repair can be made.

Loose or missing teeth and stops can cause

trouble. If teeth or stops are not tightened, they

will eventually be lost and tear the bead. In

repairing such damage, see that the loose stop is

in position (almost touching teeth), and then set

tightly with stop-closing pliers. Set any loose teeth

parallel with the other teeth in the chain, and then

apply pressure with the stop-closing pliers. Set any

loose teeth parallel with the other teeth in the

chain and apply pressure with the stop-closing

pliers. If a replacement stop is not available in

the repair kit, a soft wire or heavy thread may

be used as a temporary stop.

A missing tooth should be repaired by

replacing the entire interlocking slide fastener.

However, in the event that there are no spare

fasteners available, a missing tooth may be

replaced. This is done by carefully removing the

stop from the top of the chain, taking off the top

tooth, replacing the stop, and setting the tooth

in place. (You should be careful not to damage

the bead of the chain when resetting the tooth.)

You may run into trouble in moving the slider

on the chain. This is caused by the jaws of the

slider being too tight, or a dirty chain maybe the

trouble. To loosen the slider, insert a screwdriver

between the jaws, and very gently pry them apart

until they operate freely.

Should the slider become jammed with fur,

wool, or other material, carefully remove such

matter with a pin or needle while gently pulling

the slider until it is released. If it is so badly

jammed that it resists all efforts, remove the slider

by carefully bending the jaws apart and returning

the jaws to their original position. Then replace

the slider on the chain (described later).

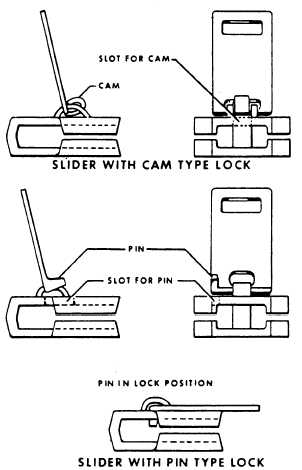

Most pull tabs have two small projections

fitting into slots on each side of the slider. To

remove the pull tab, use two pairs of pliers, one

on each side, and twist in opposite directions. In

10-17