turn the screw clockwise. To decrease the tension,

turn the screw counterclockwise.

The tension on the machine and bobbin

threads should be checked by test-running a row

of stitches on scrap material. The lockstitch

should lock in the center of the material, as

described for the 31-15. When sewing webbings

with the 7-33 sewing machine, the specifications

for webbing sewing should be checked to

determine at what ply of the webbing the stitch

should lock.

Regulating the Length of Stitch

The procedure for regulating the stitch on

the 7-33 ‘sewing machine

31-15.

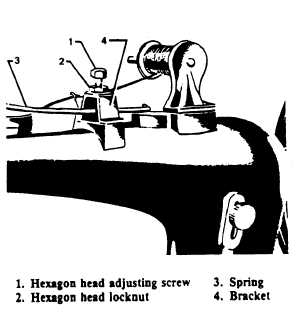

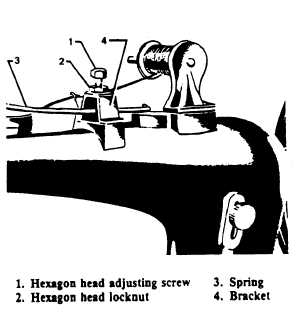

Regulating the Pressure

on the Material

is the same as for the

The pressure on the material is regulated by

means of the hexagon head screw (1). (See figure

9-22.) Loosen the hexagon head locknut (2) and

turn the adjusting screw clockwise to increase the

pressure, or counterclockwise to decrease the

pressure on the spring (3). When the desired

pressure has been obtained, hold the adjusting

screw with a wrench to keep it from turning while

239.279

Figure 9-22.—Regulating the pressure on the material.

9-17

the locknut is being tightened against the bracket

(4).

The pressure should be just heavy enough to

enable the feed dog to move the work along

evenly, and to prevent the work from rising with

the needle.

Preparing the Sewing

The same sewing preparatory procedures are

used for the 7-33 as for the 31-15 sewing machine,

except there is no knee lifting device. The hand

presser bar lifter is the only device provided for

lifting the presser foot on the class 7-33 sewing

machine.

Removing the Work

Stop the machine and raise the thread take-

up lever to its highest position. Draw about 3

inches of thread through the thread retaining

disks. Raise the presser foot and draw the work

back, cutting the threads close to the material.

Leave the ends of the threads under the presser

foot .

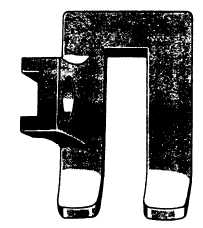

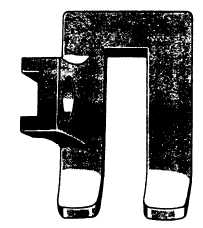

Modification of Presser

Foot for Webbing Sewing

The modification of a presser foot is illustrated

in figure 9-23. The presser foot should be cut

239.280

Figure 9-23.—Modification of presser foot for webbing

sewing.