CABLE ANCHOR DAMPER

LEARNING OBJECTIVE: Describe the

components of the cable anchor damper.

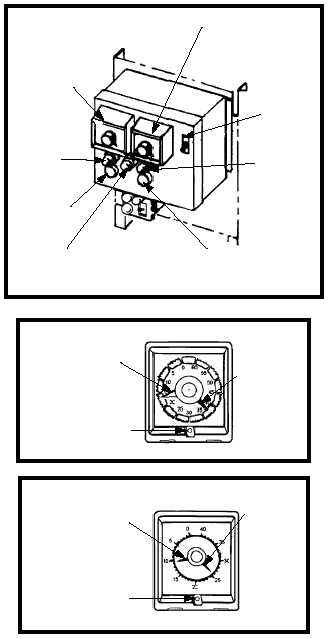

The cable anchor damper installation consists of

two identical anchor damper assemblies. In most cases

one cable anchor damper assembly is deck mounted

and the second assembly is overhead mounted (fig.

3-20). Compartment configuration determines how the

units are installed.

The purpose of the cable anchor damper is to

eliminate excessive purchase cable slack between the

crosshead and fixed sheave assembly at the beginning

of the arrestment stroke. Through service use and

experimental testing, it was found that when this cable

slack was taken up by the landing aircraft, excessive

vibrations occurred in the engines. The cable anchor

damper removes this slack as it occurs, thereby

eliminating vibration of the purchase cable. The cable

anchor damper assembly is used with pendant engines

only.

Referring to figure 3-20, note that each cable

anchor damper assembly includes a cylinder that

connects to an operating end head and a cushioning end

head. Piping connects the engine cylinder to the

operating end head through a manifold tee. Two lines

branch from the manifold tee, one to each damper

assembly operating head. Each of these lines contains a

flow control valve. A cover is placed over the operating

piston rod and coupling assembly for safety of

operation and protection against foreign matter. Each

damper assembly is mounted on a base before

installation.

A battery positioner, actuated by the retracting

lever, is provided to ensure the return of the damper

assembly

to

the

BATTERY

position

after

an

arrestment. A battery-position indicator is provided to

indicate when the cable anchor damper is in the

BATTERY position, ready for aircraft engagement.

The

limit

switch

and

cam

actuator

for

the

battery-position indicator are located on the cable

anchor damper assembly, and the indicator lights are

located on the arresting engine control panel.

The end of the purchase cable is attached to the

operating end piston rod by an anchor damper coupling.

When the force on the operating piston, due to engine

cylinder pressure, is greater than the tensile force in the

purchase cable, the piston moves away from its

BATTERY position. Movement of the operating piston

into the cylinder removes the cable slack during the first

portion of the arrestment. When the slack is taken up,

the operating piston resists the return of the cable, thus

keeping

it

taut

and

preventing

excessive

cable

vibration.

3-21

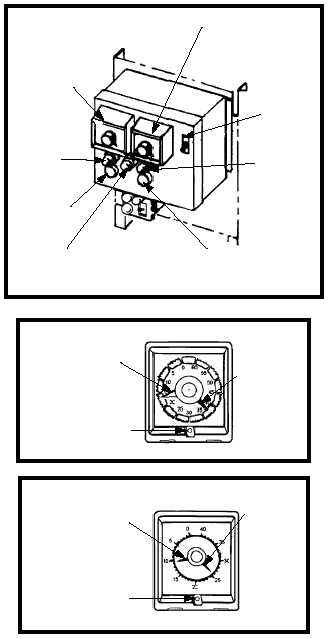

MONITOR

TIMER

(DETAIL A)

COUNTER

(DETAIL B)

ON/OFF

SWITCH

FAULT

(RED)

MANUAL RUN

READY

(GREEN)

RESET

LUBE

(AMBER)

LUBRICANT CONTROLLER

RED CYCLE PROGRESS POINTER

REGISTERS COUNTS

REMAINING TRAVELS TO

"0" DURING COUNT

ORANGE CYCLE PROGRESS

POINTER REGISTERS TIME

REMAINING TRAVELS TO

"0" DURING COUNT

LOCKING

SCREW

LOCKING SCREW

BLACK TIME SET

POINTER HAS

FULL SCALE

ADJUSTABILITY

THROUGH 320o

BLACK SET

POINTER HAS

FULL SCALE

ADJUSTABILITY

THROUGH 320o

DETAIL A

DETAIL B

ABEf0319

Figure 3-19.—Automatic lubrication controller.