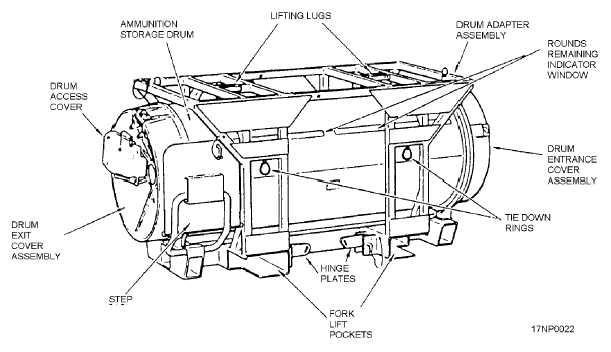

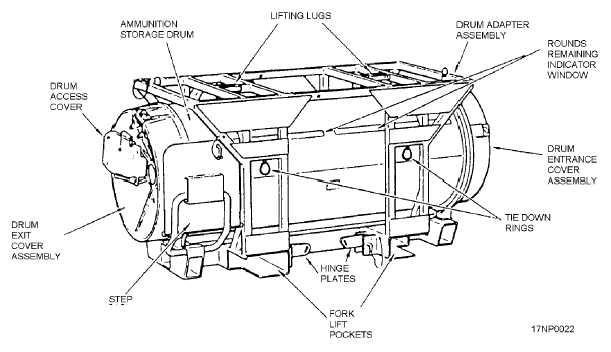

The drum adapter assembly is a box-type structure

that allows the transporters to be stacked. Four hinge

plates and four quick-release pins are used to lock the

transporter onto the MHU-191/M transporter. Two

lifting lugs (on 30-inch centers) mate with a weapons

carrier so that an overhead crane can be used to lift the

transporter. Additionally, there are two forklift pockets

that allow the forklift truck to move the transporter.

There are four tie-down rings to secure the transporter

to the deck. Foldout steps, if needed, are located at the

exit end of the transporter to provide personnel with the

additional height to operate the LALS.

The ammunition drum is a cylindrical structure that

consists of an outer drum structure, an inner drum, two

scoop disk assemblies, and two cover assemblies.

OUTER DRUM.—The outer drum is a storage

container for ammunition, and it provides a housing for

the inner drum. There is a rounds-remaining indicator

window so you can determine the number of rounds

remaining in the drum. The drum partitions, mounted

longitudinally within the outer drum to hold the rounds

in place, hold the rounds radially around the outer drum

with their bases in an outward direction.

INNER DRUM.—The inner drum is a welded

assembly with a mounting ring at each end. There are

sheet metal leaves welded to the outer surface of the

core that form a double-lead helix. When the inner

drum is rotated, it moves the rounds along the drum

partitions from the entrance end to the exit end of the

drum.

SCOOP DISK ASSEMBLIES.—A scoop disk

assembly is mounted on each end of the inner drum.

There are three rails on the scoop disk assemblies,

forming a continuation of the inner drum helix. Also,

two sets of gear-driven sprockets and scoop extensions

are located on the scoop disks 180 degrees apart. These

sprockets and scoop extensions transfer the rounds

from the entrance cover to the outer drum partitions and

from the outer drum partitions to the exit cover. The

entrance scoop disk has two pins that hold the scoop

extensions closed when they are activated by a cam in

the outer drum. This prevents feeding rounds into the

empty space where the drum partitions cannot control

the rounds.

DRUM COVER ASSEMBLIES.—A drum cover

assembly is mounted on each end of the outer drum.

The drum cover assemblies accept rounds from the

entrance unit, load units, or from the scoop disk

assembly. It then places the rounds into the scoop disk

assembly (entrance end) or exit unit, respectively. The

retainer partitions on the retainer gear maintain control

of the rounds between the scoop disk assemblies and

the entrance or exit units. A spring-loaded timing pin on

each drum cover is used to index the drum during

installation of the entrance and exit units. The exit drum

cover assembly also contains brackets for mounting a

drive assembly.

7-11

Figure 7-13.—Transporter.