where contact between wire rope and the component

being lifted could result in damage.

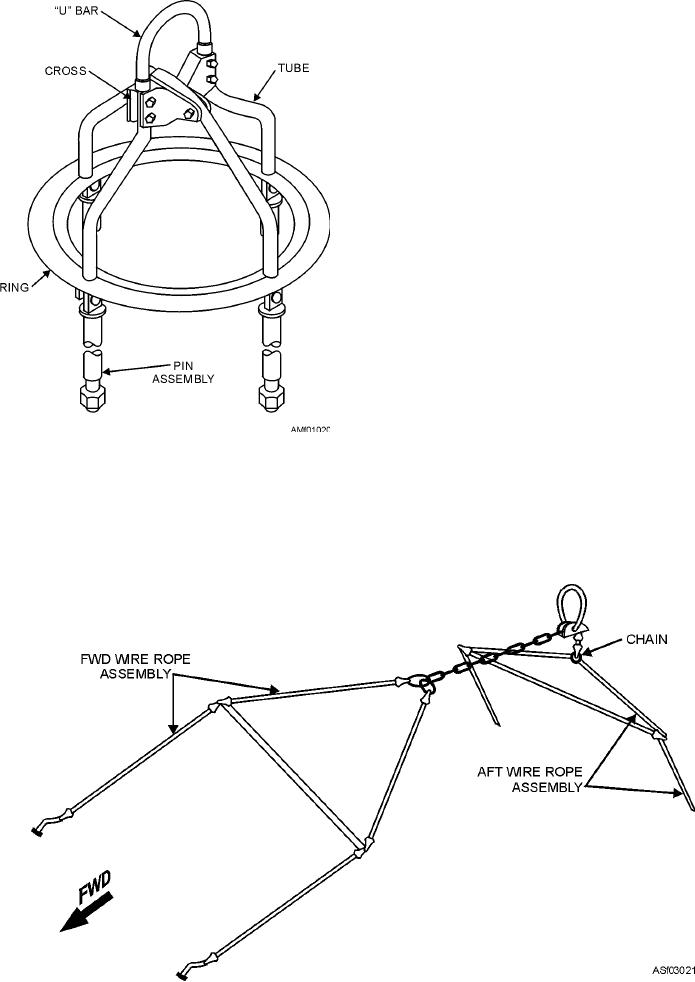

Structural Steel or Aluminum

Slings of this type are constructed with plates,

tubing, I-beams, and other structural shapes, and they

do not contain flexible components. See figure 1-20.

Structural steel and aluminum slings are generally

compact in size, and they are often used for lifting

aircraft subassemblies.

Chains

Chains are generally used in combination with one

of the other types of sling construction. See figure 1-21.

A chain with a chain adjuster provides a simplified

method of shifting the lifting point on a sling to match

the component's center of gravity under a variety of

hoisting configurations.

LIFTING SLING MAINTENANCE

Figure 1-20.--Typical steel/aluminum sling.

Load-bearing cables, chains, straps, and other

structural members of hoisting and restraining devices

are subject to wear and deterioration. It is necessary

Fabric or Webbing

that these components be inspected and lubricated

Fabric or webbing type slings are generally

periodically to ensure safe and proper operation. On

reserved for lifting lightweight objects, or applications

initial receipt of equipment or return of equipment from

Figure 1-21.--Combination wire rope and chain sling.

1-26