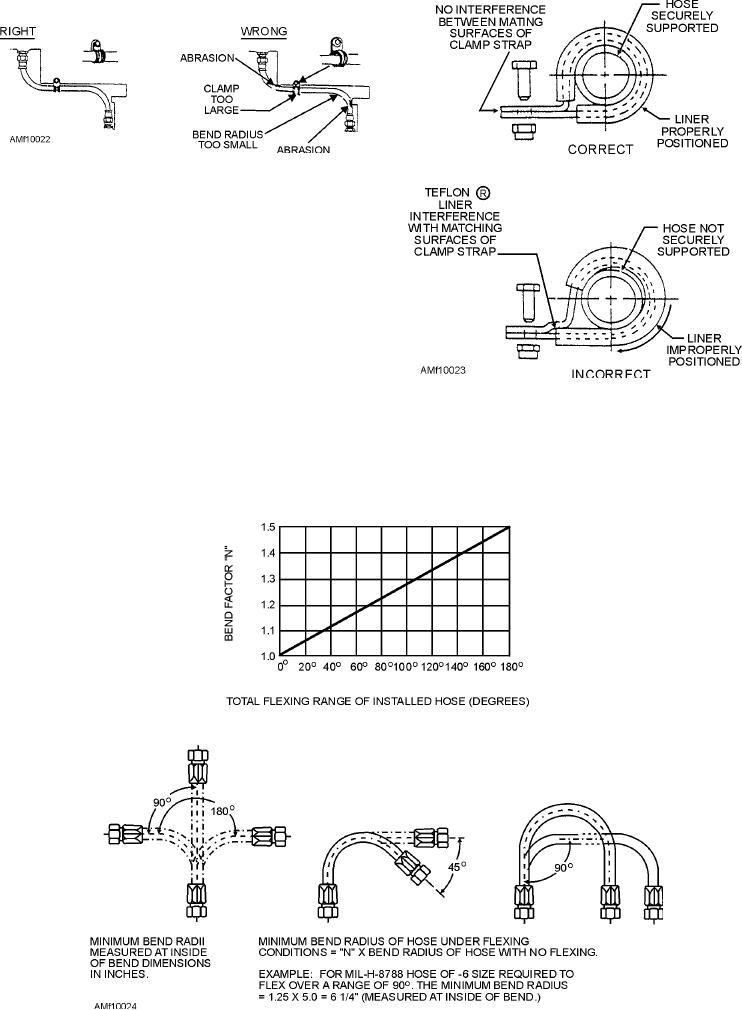

Figure 10-22.--Hose clamp mounting.

assembly securely to avoid abrasion and kinking where

flexing occurs (fig. 10-22).

Overtightening clamps will squeeze or deform

hose. Cushion-type clamps should be used to prevent

hose chafing. See figure 10-23.

Make sure support clamps do not restrict hose

travel or subject hose or hose assembly to tension,

torsion, compression, or sheer-stress during flexing

Figure 10-23.--Clamp installation.

cycles. Where flexing is required in an installation,

bend the hose in the same plane of movement to avoid

twisting. Ensure that the minimum bend radius is

Age Control and Service Life

greater by a factor of "N" than the minimum bend

radius for a nonflexing hose for hose assemblies

Hose or hose assemblies fabricated from

required to flex at a bend (fig. 10-24).

age-sensitive materials are subject to age control. The

Figure 10-24.--"N" factor for flexing bends.

10-22