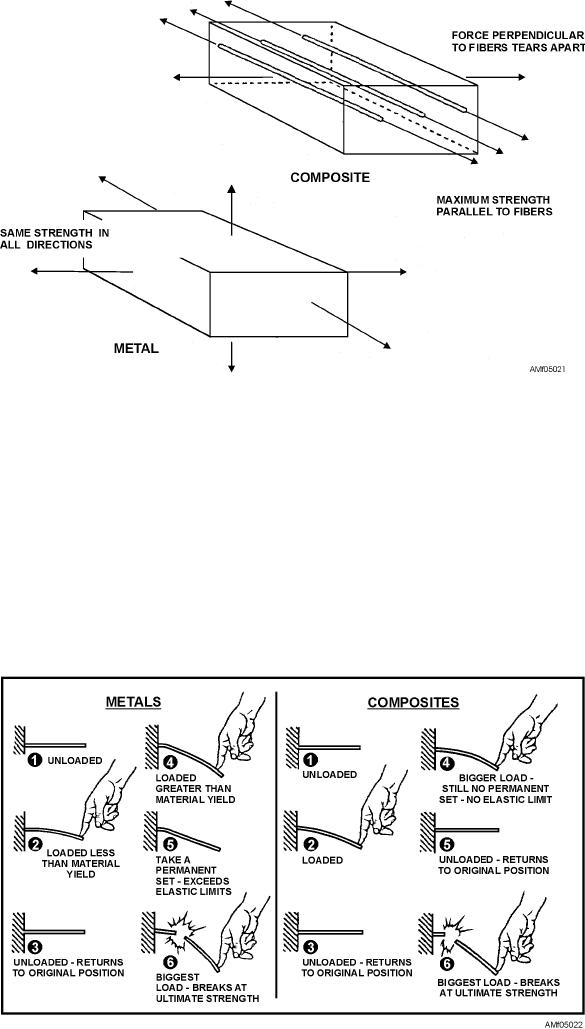

Figure 5-21.--Design properties comparison.

and mechanical strengths equal in all directions.

composition of the reinforcing materials and by the

Stresses and strains are equally transmitted in all

type of matrix materials.

directions. Composites can have different physical and

The primary factors taken into consideration when

mechanical strengths in different directions, and are

designing composites are the costs (research and

considered anisotropic or quasi-isotropic. These

development, production, fuel economy), type of

strengths are determined by the fiber orientation

application (load requirements of the structure,

patterns. The patterns are unidirectional, bidirectional

adjoining materials, service-life requirements), mission

or quasi-isotropic. Maximum strength is parallel to the

and maintenance requirements, and operational

fibers, and loads at right angles to the fibers tend to

environment (hot/cold weather, relative humidity,

break only the matrix. See figure 5-21. Metals and

altitude, land/carrier based).

composites respond differently when subjected to

The comparative properties of composites and

loads. See figure 5-22.

metals are that metals have almost the same physical

Figure 5-22.--Response to applied loads.

5-17