If the presser-lifting eccentric is not, properly timed, it can cause the machine to feed backward or prevent the machine from making the full stitch length.

The maximum stitch length of 3 1/2 SPI should beset while you are making the following adjustments:

a. Turn the balance wheel toward the operator and observe the action of the feed dogs and the front presser. They should meet at the

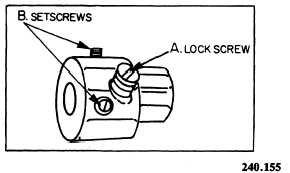

Figure 4-10A. - Presser-lifting eccentric connection link.

throat plate height and travel aft together; if theydo not, continue to step b.

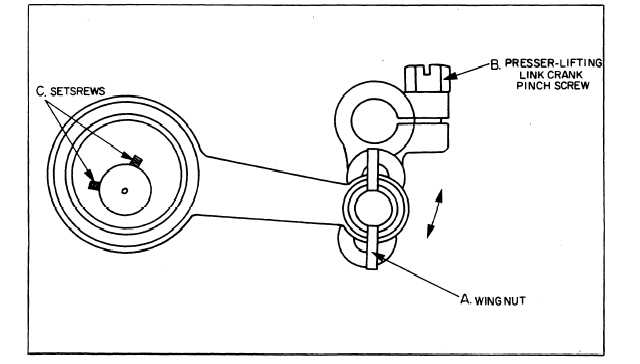

b. Turn the balance wheel and loosen the two set screws (figure 4-10B [C] and figure 4-10 [A]) on the presser-lifting eccentric.

c. Hold the eccentric to prevent it from turning; then turn the balance wheel a small amount toward the operator and tighten one of the setscrews.

d. Repeat steps b and c until the front foot meets the feed dog at the throat plate height as the balance wheel is turned toward the operator.

e. Ensure both setscrews are tight.

ADJUSTMENTS

For the sewing machine to operate smoothly and to make a proper locking stitch, you must make some minor adjustments. Even though the machine is in time, a single part that is out of adjustment can cause the sewing machine to skip stitches, break thread, fail to feed the material, or make loose stitches.

1. Adjusting the bobbin-case opener

As the hook rotates clockwise, friction on the bobbin-case opener causes the position lug

Figure 4-10B. - Presser-lifting eccentric.

Continue Reading