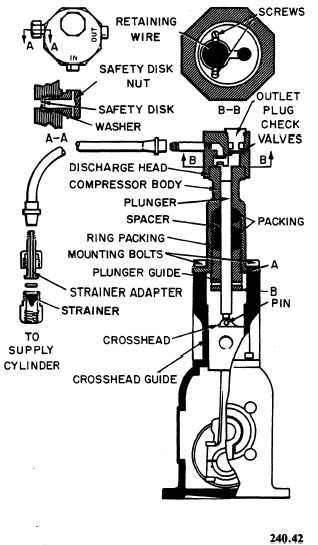

vapor leak will not affect the performance of the pump; no particular effort need be made to eliminate a leak unless it reaches the point at which it becomes visible. If a leak should develop at the lower end of the plunger, tighten the plunger guide, shown in figure 3-8, with a rod (approximately 3/8 inch by 6 inches). Do not bind the plunger by tightening it too snugly. When you can no longer adjust the tightness of the plunger guide, remove the compressor body from the frame and insert new packing as follows:

1. Unscrew the four bolts that hold the compressor body to the crosshead guide and remove the pin that holds the plunger to the crosshead.

Figure 3-8. - Compressor assembly of the Walter Kidde CO2 transfer unit.

2. Place the compressor body in a vise and remove the plunger guide and old packing. Insert only the two large pieces of packing and the spacer. Then insert the plunger guide and turn it down as far as possible to compress and form the packing around the plunger. This operation will cause the plunger to bind, but you can free it by turning and working the plunger up and down a few times.

3. Remove the plunger guide and insert the small ring of the packing. Install the packing so that the level fits the packing already in place and the plunger guide. Replace the plunger guide and turn it in until the maximum dimension between the body at point (A) and the end of the plunger guide (B) (figure 3-8) is 1 3/16 inches. If the plunger guide is not screwed in sufficiently, the crosshead will strike the plunger guide. To free the plunger, work it back and forth several times.

4. Replace the compressor body and extend the plunger so that it can be lined up with the crosshead and the pin being replaced. After you connect the end of the plunger with the crosshead, which may have had to be moved to its top position to accomplish the connection, tighten the bolts securely. Turn the master gear several revolutions by hand to make sure the crosshead does not strike the plunger guide.

Safety Disc

Figure 3-4 and 3-5 illustrate the safety disc arrangement located in the discharge body. The method of removal and replacement of the safety disc is self-evident in the illustration; however, never use a disc that is stronger or weaker (tensile strength capacity) than specified.

Cleaning

No foreign matter should be in the areas of recharging pump connections. If a decrease is noted in the amount of carbon dioxide transferred (it should be approximately 80 percent of the supply cylinder), remove the two check valves (figure 3-5) in the compressor head and clean them. To do this, remove the discharge head body (right-hand thread). Then remove two screws and the retaining wire. The inlet check will then be accessible. You can remove the outlet check by unscrewing the plug. Clean both checks and the seat thoroughly.

The strainer on the inlet line (from the supply cylinder) should be cleaned frequently for maximum efficiency of the pump.

Continue Reading