PREVENTIVE MAINTENANCE

If the sewing machine becomes sluggish, an accumulation of dust and lint or a loose power belt may be the cause. To prevent the buildup of dust and lint, you should cover the sewing machine when it is not in use.

CLEANING AND OILING

Before you attempt to oil or operate a new sewing machine, clean it with diesel fuel. The diesel fuel removes any corrosion-protective lubricants that may have been placed on the sewing machine at the factory. During normal maintenance, you may use any approved cleaning solvent to clean the sewing machine.

After you use a sewing machine, clean and oil it. A clean and well-oiled sewing machine gives you many hours of trouble-free operation. You may clean hard-to-reach places with a soft-bristle brush or air pressure. Clean the outside of the sewing machine head, the oil pan, the machine stand, and the motor casing with a clean dust cloth or air pressure. Never use air pressure above 25 psi for this purpose.

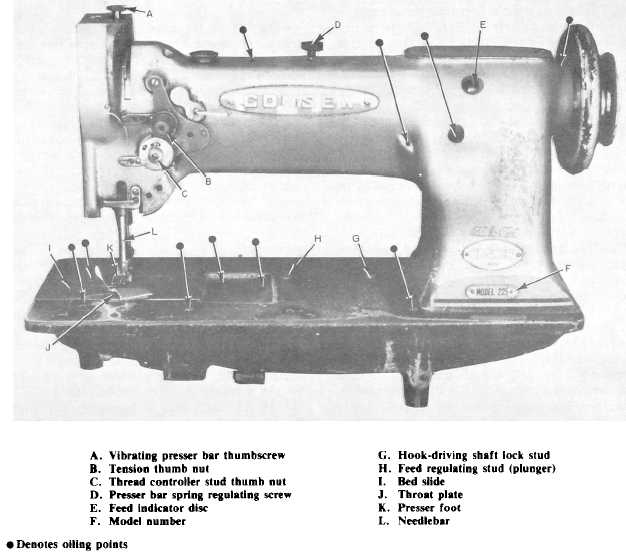

NOTE: At least once a year, the machine should be thoroughly cleaned and oiled. Figures 4-1 through 4-3 show the oiling points on the 111

Figure 4-1. - Front view of Model 225 sewing machine showing oiling points.

Continue Reading