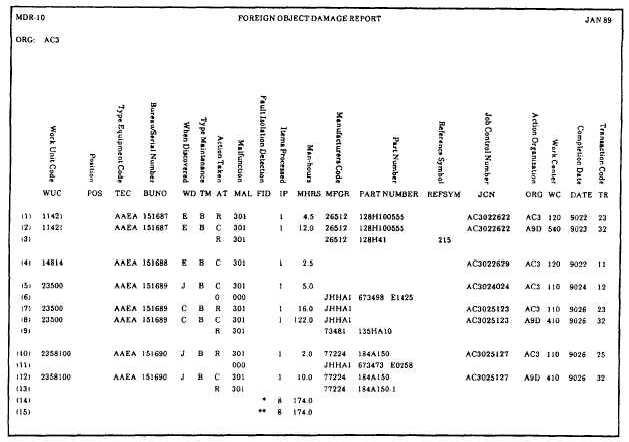

FOREIGN OBJECT DAMAGE (FOD) REPORT (MDR-10)

This report is used to measure the maintenance effort attributable to FOD. Components replaced, repaired, condemned, etc., can be identified by the data in the MDR file. Indirectly, the report reflects housekeeping conditions (cleanliness of ramps, runways, hangar area, etc.) or the maintenance methods of personnel (adherence to proper maintenance practices (fig 5-22). The source of data for this report is the VIDS/MAF (excluding transaction code 72), which contains malfunction code 301.

CORROSION CONTROL/TREATMENT REPORT (MDR-11)

This report is designed for monitoring the Corrosion Control Program or for investigating the amount of corrective corrosion treatment necessary (fig. 5-23). Support action code 04 and malfunction code 170 are the two sources of information that are used to identify these areas. It is a simple matter to determine whether any specific portion of the aircraft, by work unit code, needs a better corrosion control program. This report is subject to change due to the deletion of the Support Action Form (SAF).

NO DEFECT REPORT (MDR-12)

This report shows the amount of time and effort expended on maintenance for which there is no malfunction (fig. 5-24). This report can be used to determine man-hours expended in removing or installing items with no known malfunction, solely to facilitate other maintenance.

WHEN MALFUNCTION WAS DISCOVERED REPORT (MDR-13)

This report shows the action taken by category of each when discovered code

Figure 5-22.-Foreign Object Damage Report (MDR-10).

Continue Reading