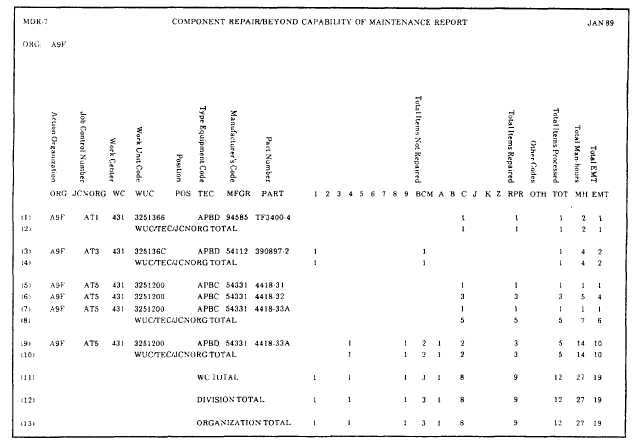

COMPONENT REPAIR/BEYOND CAPABILITY OF MAINTENANCE (BCM) REPORT (MDR-7)

This report provides a spread of action taken codes for maintenance actions taken by the intermediate level and provides the maintenance officer and the maintenance/material control officer with an overview of the entire production effort of the activity by work center and work unit code within a type equipment (fig. 5-19). The report can be used to determine the percentage of components received at the intermediate maintenance activity (IMA) that do not require any repair.

FAILED PARTS/PARTS REQUIRED REPORT (MDR-8)

This report is prepared from data submitted 32 and a malfunction code (not 000) entered in the (H-Z) Failed/Required Material block (fig. 5-20). This report is intended for the maintenance officer, material control officer, and work center supervisors. The report can be used to identify part numbers that have a high awaiting parts (AWP) time.

REPAIR CYCLE DATA REPORT (MDR-9)

This monthly report is a detailed list, by organization, showing the number of days of turnaround time and the elements that compose the turnaround time for each repairable component processed through the intermediate maintenance activity as documented on the VIDS/MAF, or Metrology Equipment Recall (METER) card (fig. 5-21). This report can be used to identify components that appear repeatedly in on the VIDS/MAF with transaction code 12 or the intermediate level repair cycle.

Figure 5-19.-Component Repair/Beyond Capability of Maintenance (BCM) Report (MDR-7).

Continue Reading