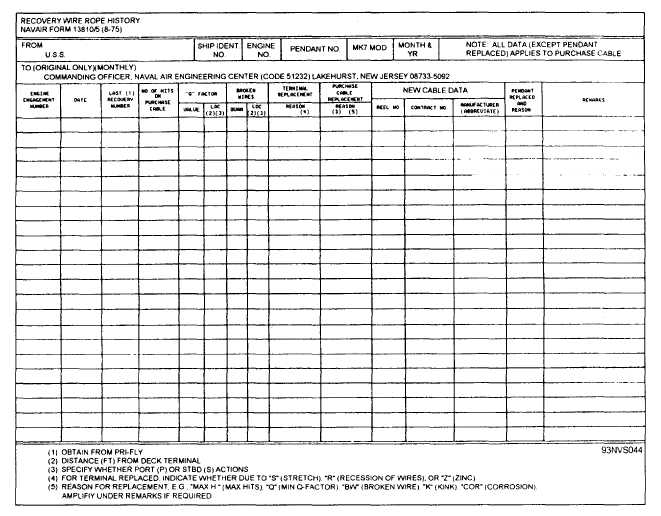

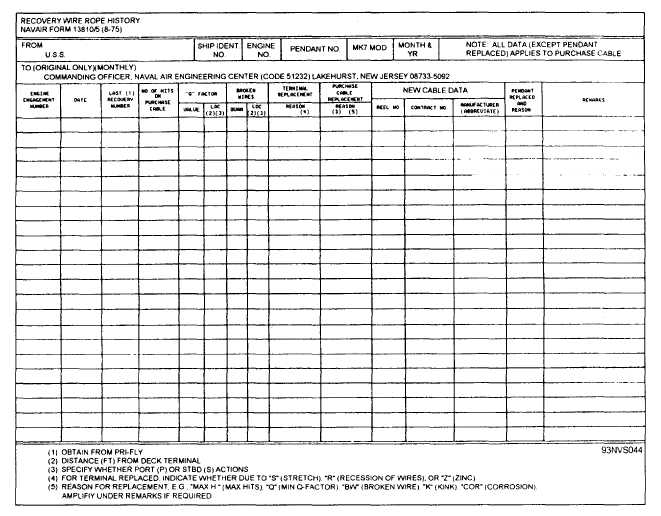

Figure 3-44.—Recovery Wire Rope History chart (NAVAIR Form 13810/5).

fairlead pipes and wrap around the sheaves before

pulling in the purchase cable.

2. To thread the cable through the deck and

fairlead sheaves, remove the sheave covers and pull

out the sheaves. Push the cable through the fairlead

pipes from sheave housing to sheave housing. Then

slip the cable into the sheave groove as the sheave

is replaced in the housing. When the cable is fully

threaded, replace the covers.

3. In reeving the engine, use only the original,

approved reeving pattern.

Study the reeving

diagram in the applicable NAVAIR maintenance

manuals, and be careful to pass the cable over the

sheaves in the approved sequence and through the

appropriate fairleads and guides.

4. After the cable is reeved, the next step is to

connect the anchor end of each length. Then the

cable must be stretched taut to determine the

correct location for the terminal

end.

of the opposite

New cables acquire a stretch over the course of

the first several engagements. This lengthening of

cables decreases the distance between crosshead and

crosshead stop in the BATTERY position, and this

in turn increases the fluid capacity of the hydraulic

system and makes it necessary to add fluid to

maintain the fluid level.

If the distance from

crosshead to crosshead stop in the BATTERY

position becomes less than the minimum allowable

clearance of 1 inch between the crosshead and the

crosshead stop, it becomes necessary to crop the

cable and repour a terminal to readjust the

clearance to 7 inches between the crosshead and the

stop. The clearance between the crosshead and

crosshead stop with newly installed purchase cables

is set at 9 inches. New purchase cables will stretch

very rapidly during the first few arrestments. The

initial 9-inch dimension between the crosshead and

3-49