necessary, while component repair is in process.

Metallic wipers are formed in split rings for ease in

installation, and they are manufactured slightly

undersize to ensure a tight fit. One side of the

metallic wiper has a lip, which should face outward

upon installation. Metallic wipers must be inspected

for foreign matter and condition, and then installed by

sliding them over the piston shaft in the proper order,

as directed by the applicable MIM.

The felt wiper may be a continuous felt ring or a

length of felt with sufficient material to overlap its

ends. The felt wiper should be soft, clean, and well

saturated in hydraulic fluid during installation.

Protective Closures

Contamination is hazardous and expensive. To

protect hydraulic systems from contaminants, use

protective closures.

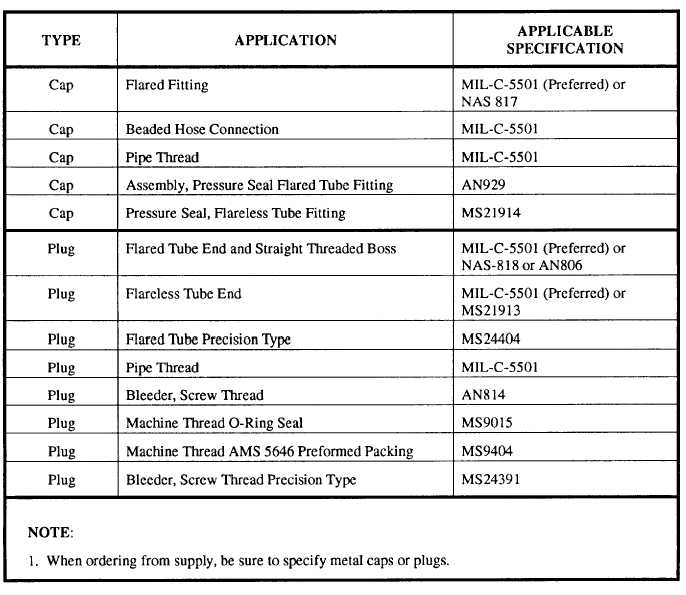

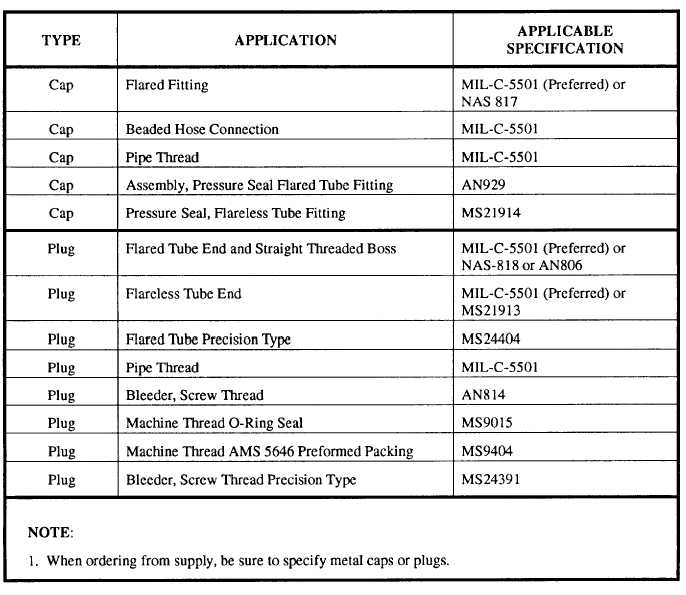

Two types of protective metal

closures are approved for sealing hydraulic

equipment. They are caps and plugs conforming to

appropriate military specifications. Guidelines for

selection and use of protective closures for hydraulic

equipment are as follows: Use caps and plugs of the

proper size and material. Never blank-off openings

with wooden plugs, paper, rags, tape, or other

unauthorized devices.

Use closures of metal

construction conforming to specifications listed in

table 2-2 for sealing hydraulic system equipment,

lines, tubes, accessories and components.

Table 2-2.—Protective Caps and Plugs

2-41