2. Slide the sleeve (with the sleeve seal partially

installed) onto the line.

3. Position the split sleeves over the line beads.

4. Slide the sleeve over the split sleeves, and fold

over the sleeve seal so it covers the entire sleeve.

5. Install the coupling over the sleeve seal and

torque to correct value.

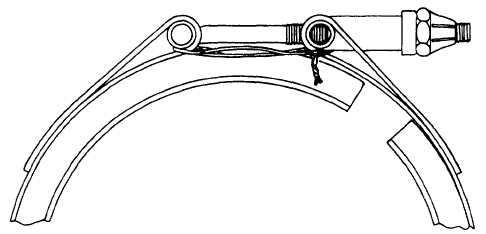

RIGID COUPLINGS.—The rigid line coupling

shown in figure 2-15 is referred to as a V-band

coupling. When you install this coupling in restricted

areas, some of the stiffness of the coupling can be

overcome by tightening the coupling over a spare set

of flanges and a gasket to the recommended torque

value of the joint. Tap the coupling a few times with

a plastic mallet before removing it.

When you install rigid couplings, follow the steps

listed below:

1. Slip the V-band coupling over the flanged

tube.

2. Place a gasket into one flange. One quick

rotary motion assures positive seating of the gasket.

3. Hold the gasket in place with one hand while

the mating flanged tube is assembled into the gasket

with a series of vertical and horizontal motions to

assure the seating of the mating flange to the gasket.

NOTE: View B of figure 2-15 shows the

proper fitting and connecting of a rigid

coupling using a metal gasket between the

ducting flanges.

4. While holding the joint firmly with one hand,

install the V-band coupling over the two flanges.

5. Press the coupling tightly around the flanges

with one hand while engaging the latch.

6. Tighten the coupling firmly with a ratchet

wrench. Tap the outer periphery of the coupling with

a plastic mallet to assure proper alignment of the

flanges in the coupling.

This will seat the sealing

edges of the flanges in the gasket. Tighten again,

making sure the recommended torque is not

exceeded.

7. Check the torque of the coupling with a torque

wrench and tighten until the specified torque is

obtained.

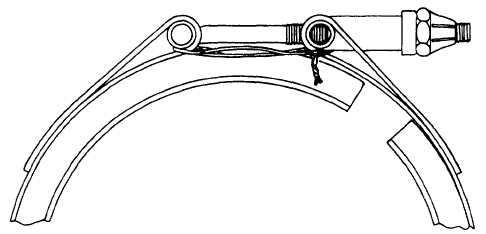

8. Safety wire the V-band coupling, as shown in

figure 2-16, as an extra measure of security in the

event of T-bolt failure. The safety wire will be

installed through the band loops that retain the T bolt

and the trunnion or quick coupler. A minimum of

two turns of the wire is required. Most V-band

connectors will use a T bolt with some type of

self-locking nut.

TAPER PINS.—Taper pins are used in joints that

carry shear loads and where the absence of clearance

Figure 2-16.—Safetying a V-band coupling.

2-13