flags and rapid access to them. It also keeps them clean

and, with the canvas cover in place during inclement

weather, dry. Flags should be washed in the ship's

laundry periodically. Only mild soap and warm water

(not hot) should be used for cleaning flags. Grease

spots can be removed with dry-cleaning solvents.

Damp or wet flags are mildew prone. When flags

are wet, dry them as soon as possible by hoisting them

on the signal halyards. This should not be done when

under way or when in high winds. Air bunting is an

excellent way to dry flags. This can be done on request

from the senior officer present.

REPAIR OF FLAGS

Although ships carry spare sets of flags,

Signalman strikers or third class petty officers may be

assigned to repair bunting. If a bunting space is

available, it will contain a sewing machine, bunting,

thread, tapes, and tabling material. If a bunting repair

space is not available, repairs may be done by using a

sewing machine located in the deck spaces. When

repairing flags, never mix materials. Wool and cotton

shrink differently, and combinations invariably

become misshapen after the first wetting. For correct

dimensions, refer to NTP 13, Flags, Pennants and

Customs.

HALYARDS

2-21

Signal halyards are made of either nylon or natural

color braided cotton line. The braided cotton line is no

longer used aboard ship, because it could not hold up

under the effects of ships' high speeds, stack

temperatures, and gases. Ashore, however, cotton

halyards are still used. Double-braided 1 l/8-inch

nylon rope is required by the Board of Inspection and

Survey (INSURV). Double-braided 1 l/2-inch nylon

rope is permitted alternately with twisted rope for

dressing lines. The twisted nylon and double-braided

nylon rope withstand the heat and gases much better

than braided cotton line.

Halyard blocks are single, roller-bushed sheave

blocks. They are attached by means of sister hooks to

U-bolts welded to the yardarms. Those attached to

stays and mastheads may be of other construction,

adapted to the construction of the stay or masthead.

CARE OF HALYARDS

When reeving halyards through signal halyard

blocks, always reeve forward to aft. Rings and snaps

on halyards are put on with a halyard eye splice.

Splicing double-braided nylon rope is explained and

illustrated in the following section.

At night and during inclement weather, ease off

the halyards to prevent unnecessary strain cased by

shrinkage. At other times, however, keep halyards

clear and taut to give the signal bridge a sharp

appearance. Periodically check the condition of the

halyards. Replace them before they become too worn.

SPLICING DOUBLE-BRAIDED LINE

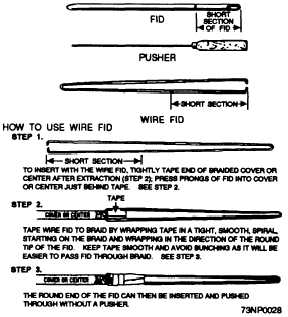

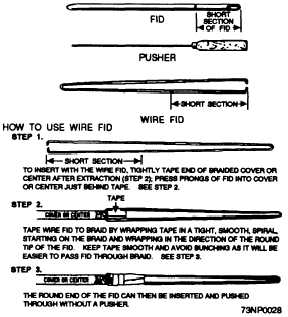

When double-braided nylon line is being spliced,

the end must be worked into the center, and special

tools are needed for the job. For line 3 inches in

circumference or smaller, a fid and pusher are used.

For line larger than 3 inches in circumference, only a

wire fid is used. Steps 1, 2, and 3 in figure 2-22 show

how to secure the fid to the line. Stamped on each fid

is a number indicating the size of line for which the

fid was made. Fids also serve as rulers to measure with

while splicing is being done. The wire fid lengths in

figure 2-23 are in l/2 and l/3 scale. Friction or

masking tape and a soft lead pencil, crayon, or

preferably, a wax marking pencil are needed.

Sharp-pointed shears also are handy.

The splice described here, and the line on which

it is used, were developed by the Samson Cordage

Works of Boston, Massachusetts.

Figure 2-22.—Fids used for splicing double-braided line.