shape) on the body belt. When you are at working

position, you unsnap one end of the safety strap, pass it

around the supporting structure so there is no danger of

its slipping (at least 18 inches from the top of the part on

which it is fastened), and hook it to the right D-ring on

the body belt.

The safety strap must be placed around a part of the

structure that is of sufficient strength to sustain an ABs

weight and his or her equipment, and must rest flat

against the surface without twists or turns. It must not

be placed around any part of a structure that is being

removed.

Before placing your weight on the strap, determine

VISUALLY that the snap and D-ring are properly

engaged. Do not rely on the click of the snap-tongue as

an indication that the fastening is secure.

The body belt and safety strap require inspection

before use. Look for loose or broken rivets; cracks,

cuts, nicks, tears or wear in leather; broken or otherwise

defective buckles, such as enlarged tongue-holes,

defects in safety-belt snap hooks and body belt D-rings.

If you discover any of these or other defects, turn in

your equipment and replace it.

Perform maintenance periodically according to

applicable procedures. Remember that leather and

nylon belts are treated in different manners.

1-3

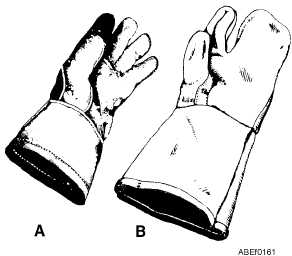

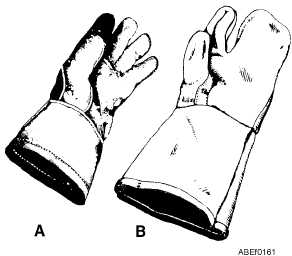

Figure 1-2.—Gas and electric-arc welding gloves.

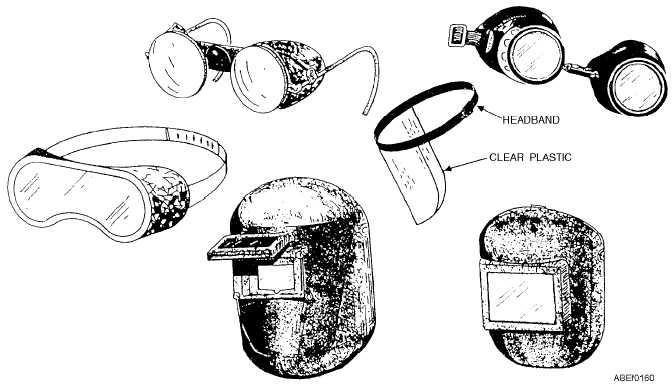

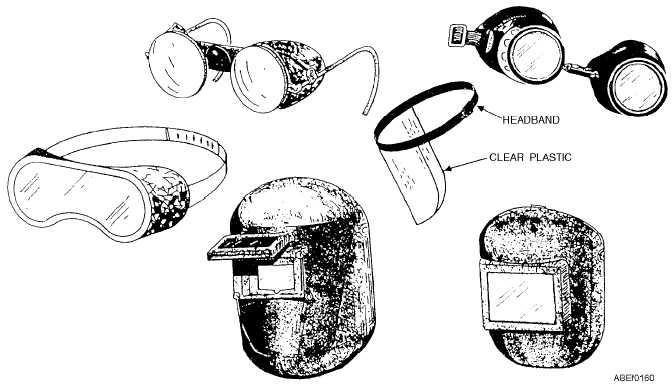

Figure 1-1.—Eye-protection devices.

Figure 1-3.—Safety equipment.