BUTTERFLY EXHAUST VALVE

The butterfly exhaust valve (fig. 4-12) provide the

means to direct spent steam from the launching engine

cylinders overboard after the launch valve closes at the

completion of a launch. The exhaust valve is attached to

the bottom flange of the thrust/exhaust unit or exhaust

tee; it consists primarily of a valve body, a disc, and a

hydraulic actuator. Prior to launch, hydraulic pressure

is directed from the exhaust valve hydraulic lock valve

to the closing port of the hydraulic actuator causing the

piston to move downward and the disk within the valve

body to move onto its seat. A switch is then actuated

that energizes a portion of the electrical circuitry that

allows the launch sequence to continue. After a launch,

when the launch valve closes, hydraulic pressure is

directed from the exhaust valve hydraulic lock valve to

the opening port of the hydraulic actuator causing the

piston to move upward and the disk within the valve

body to move off its seat and release the spent steam

overboard. The limit switch is released and allows for a

portion of the electrical circuitry necessary to allow

retraction of the launching engine pistons.

PRESSURE-BREAKING ORIFICE ELBOW

The pressure-breaking orifice elbow (fig. 4-13)

prevents a buildup of steam pressure behind the

launching engine pistons when the launch valve is

closed. The pressure breaking orifice elbow is attached

to a flange on the thrust/exhaust unit or exhaust tee

above the exhaust valve assembly and contains an

orifice that is large enough to allow the escape of launch

valve steam leakage but small enough to have no

detrimental effect on catapult performance. Any steam,

which may leak through the closed launch valve when

the exhaust valve is closed, is permitted to escape

through the pressure-breaking orifice. This prevents a

build -up of pressure that could cause premature release

of an aircraft from its holdback bar restraint.

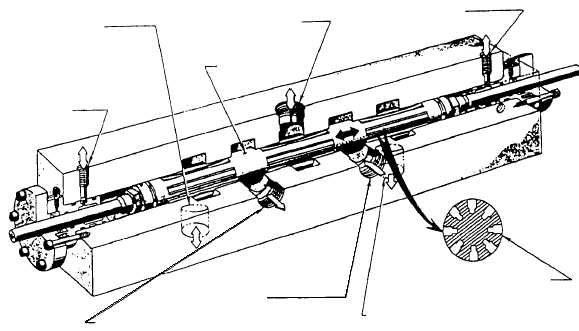

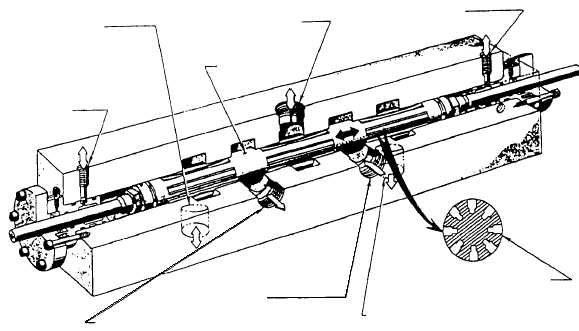

KEEPER VALVE

The keeper valve (fig. 4-14) prevents the exhaust

valve from opening while the launch valve is open. The

keeper valve is located in the piping between the launch

and exhaust valve lock valves and the closing chamber

of the exhaust valve actuator. The valve consists of a

block with an internal cylinder containing a movable

piston. The keeper valve is actuated by hydraulic fluid

from the launch-valve hydraulic lock valve. When the

launch valve opens, the piston of the keeper valve shifts

and blocks the flow of hydraulic fluid to the exhaust

valve hydraulic actuator. This prevents the exhaust

valve from opening until the launch valve is closed and

the keeper valve piston is shifted.

4-10

FROM OPERATING CYLINDER

CLOSING CHAMBER

(PORT D)

FROM LAUNCHING-VALVE

HYDRAULIC-LOCK VALVE

(PORT B)

PISTON

TO OPERATING CYLINDER

OPENING CHAMBER

(PORT A)

FROM LAUNCHING-VALVE

HYDRAULIC-LOCK VALVE

(PORT C)

PISTON CROSS SECTION

TO OPERATING CYLINDER

CLOSING CHAMBER

(PORT E)

FROM MAIN HYDRAULIC

ACCUMULATOR

(PORT G)

TO GRAVITY TANK

(PORT F)

ABEf0412

Figure 4-11.—Launch-valve control valve.