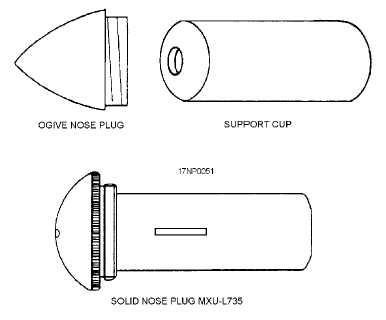

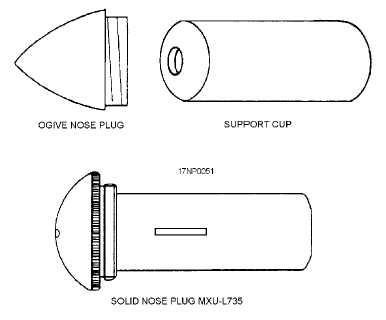

NOSE PLUGS

There are two basic nose plugs (fig. 1-17) used in

general purpose bombs, the solid nose plug

(MXU-735/B and MXU-735A/B) and the ogive nose

plug. The ogive nose plug provides a pointed arch. A

support cup is used in the nose well with the ogive nose

plug to provide a solid structure to the bomb. The

MXU-735 solid nose plug is designed to provide better

penetration of hard targets, without the likelihood of

nose plug shearing during oblique impact. The

MXU-735 replaces the ogive nose plug and support

cup.

IDENTIFICATION

The high-explosive filler of the bomb (H-6) is

identified by the yellow stenciled nomenclature on the

bomb body and yellow band(s) around the nose. The lot

number is stenciled in white ink on the forward end of

the bomb. All Mk 80 (series) general-purpose bombs

currently being used aboard ships are required to be

thermally protected. Thermally protected Mk 80 series

bombs can be identified by the words THERMALLY

PROTECTED in the identification legend, a bumpy

exterior surface, and two yellow bands around the nose.

ARMING WIRE ASSEMBLIES

Arming wire assemblies (fig. 1-18) are used for

arming procedures during ordnance evolutions. The

primary function of arming wire assemblies is to

maintain ordnance components in a safe condition until

actual release of the bomb from the aircraft.

Normally, the wires consist of one or two brass or

steel metal strands attached to a swivel loop. Safety

Fahnstock clips (fig. 1-18) or safety clips, MAU 166,

are attached to the ends of the arming wires after

installation. They prevent premature or accidental

withdrawal of the arming wires from the component.

NOTE: Safety clips are used vice Fahnstock

clips unless otherwise specified.

Normally, arming wire assemblies are shipped in

spiral-wound fiber tubes, over packed in a wooden box.

Generally, the safety Fahnstock clips are packed in the

tubes with the arming wires. The most commonly used

arming wire assemblies are listed in table 1-3.

Arming wire installation procedures are discussed

in the TRAMAN where the use of arming wire

assemblies is required.

FIN ASSEMBLIES

Fin assemblies, used with the Mk 80 (series) LDGP

bombs, provide stability to the bomb. They cause the

bomb to fall in a smooth, definite curve to the target,

instead of tumbling through the air.

The fin assemblies, except the MAU-91A/B, are

shipped on metal pallets. Each individual fin is crated in

a lightweight, disposable metal crate (fig. 1-19). Some

fin assemblies are shipped with bomb lugs attached to

the shipping crate, depending upon the particular Navy

Ammunition Logistics Code (NALC).

Two types of fins are described in this part of the

TRAMAN—conical and Snakeye. The conical fin is

1-20

Figure 1-17.—Nose plugs.