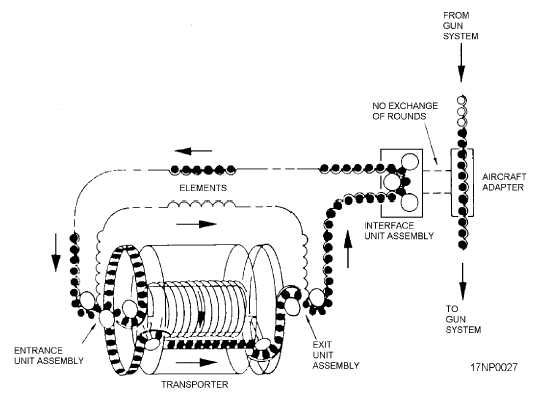

assembly mode selector is in the bypass position (fig.

7-18) and the system is cycled, the rounds are guided

around the element sprocket and into an ammunition

chute, which returns them to the entrance end of the

transporter.

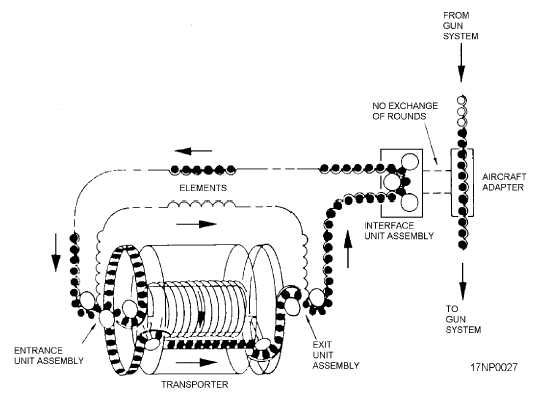

When you first connect or remove the interface unit

to or from the aircraft adapter, the interface unit

assembly must be in the bypass position. When the

interface unit assembly mode selector is in the load

position (fig. 7-19) and the system is cycled, the rounds

are removed from the elements by a sprocket and

guided into the elements in the aircraft adapter.

The rounds are carried from the aircraft adapter to

the aircraft drum. The elements entering the aircraft

adapter from the aircraft system contain spent cases or

cleared rounds. These rounds are removed from the

aircraft elements and are guided by a sprocket into the

elements of the conveyor system for transfer to the

transporter.

For further information concerning the LALS

MHU series refer to NAVAIR 19-1-125.

REVIEW NUMBER 1 ANSWERS

A1.

The Linkless Ammunition Loading System

(LALS) consists of a loader ammunition

transporter, a drum loader assembly, a

conveyor system, and a drum unload

assembly.

A2.

The LALS can hold 1,400 rounds of

electrically primed, M50/PGU ammunition.

A3.

The MHU-191/M transporter is used with the

LALS.

A4.

The loader ammunition transporter is used to

move rounds/cases through the exit and

entrance ends during operation.

A5.

The purpose of the drum loader assembly is to

load

the

transporter

with

unlinked

am-

munition.

A6.

The conveyor system is used to transport

rounds from the transporter to the aircraft

system. It simultaneously transports spent

cases and cleared rounds from the aircraft

system to the transporter.

A7.

Two gear-driven sprocket assemblies in the

exit unit assembly transfer rounds from the

transporter to the elements.

A8.

The drive power is transmitted from the

interface unit to the drum drive assembly by

the flexible drive shaft.

7-16

Figure 7-18.—Ammunition flow in bypass mode.