procedures a r e d e s i g n e d t o d e t e r m i n e p r o p e r

beyond the scope of this training course. However,

functioning and to assist in isolating and diagnosing

there should be a manufacturer's repair manual

transmission troubles.

ava i l a b l e i n t h e w o r k c e n t e r f o r t h e s p e c i fi c

transmissions for which you have maintenance

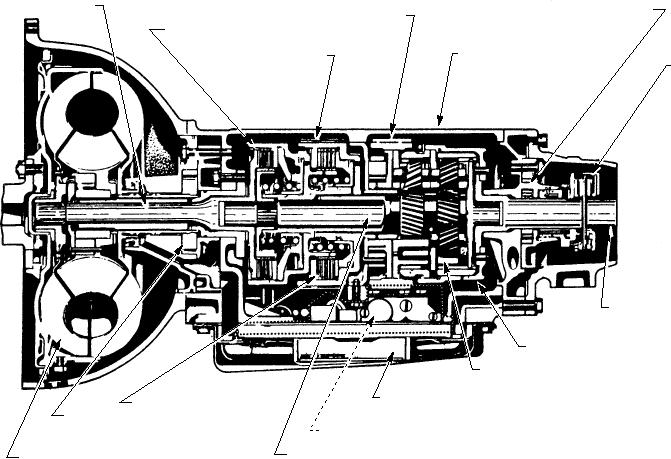

F i g u r e 2 - 7 8 s h ow s a t y p i c a l a u t o m a t i c

responsibility. These service and repair manuals

transmission, showing the range or gearing section,

should be followed very closely in performing all

operating units, hydraulic control unit (valve body),

t r a n s m i s s i o n m a i n t e n a n c e a n d r e p a i r. T h e

torque converter, pumps, governor, and transmission

maintenance discussed in the following paragraphs is

case. Optional devices such as lockup clutches,

general in nature and presented to give you a better

high-low splitters, and retarder units are not shown.

understanding of overall transmission maintenance.

You should be familiar with several terms used by

the manufacturers in describing maintenance

Adjustments

procedures for various transmissions. The term

In maintaining the automatic transmission,

apply-passage means a passage through which oil

adjustments are necessary for satisfactory

pressure is applied to an operating unit. Air-check

performance. Adjustments are required after the repair

simply means substituting air pressure for oil pressure

of a transmission and periodically while in service.

and applying it to the apply-passage for checking an

The manufacturer usually specifies the time interval

operating unit. Another term is gauging-hole, which

between most adjustments, and these

refers to holes provided in adjacent parts to hold them

r e c o m m e n d a t i o n s s h o u l d b e f o l l ow e d . T h e

in alignment or in a certain position by a gauge pin or

adjustments discussed in the following paragraphs are

rod. While the parts are held by the gauge pin, certain

the ones most commonly found on automatic

adjustments can be made.

transmissions.

A detailed step-by-step discussion of the possible

Control linkage adjustment is the adjustment of the

repairs that can be performed or how they are

selector linkage to the manual control valve. The

performed for the many automatic transmissions is

INPUT SHAFT

REAR OIL PUMP

REAR BAND

FRONT CLUTCH ASSEMBLY

TRANSMISSION CASE

FRONT BAND

GOVERNOR

ASSEMBLY

OUTPUT SHAFT

OUTPUT SHAFT DRIVE

PLANET PINION CARRIER ASSEMBLY

OIL STRAINER

REAR CLUTCH ASSEMBLY

FRONT OIL PUMP

HYDRAULIC CONTROL UNIT

INTERMEDIATE SHAFT

ASf02078

TORQUE CONVERTER

Figure 2-78.--Typical automatic transmission.

2-63